eSX 400 5-Axis Lens Grinding Machine: 5-400 mm Optics

-

Overview

eSX 400 Overview

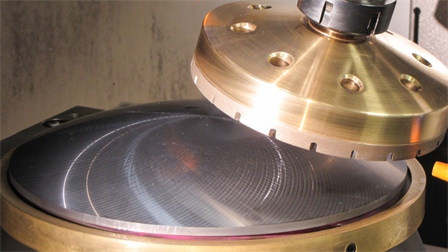

The eSX 400 lens grinding machine has 5 controllable axes: X, Y, Z, B & C with up to 5 axes of simultaneous movement. This configuration is comparable to the eSX 300, but features a larger work spindle (C-Axis), allowing optical manufacturers to grind optics 400mm in diameter (or as large as 450mm depending on geometry). The powerful Fagor 8065 CNC with user-friendly G Series software make the eSX 400 optical machining center an excellent choice for manufacturing spheres, aspheres, cylinders, freeforms and more.

Multiple advanced features on the eSX 400 help optical manufacturers achieve optimal results in terms of grinding efficiency, repeatability and surface quality after grinding:

- Better grinding: Stiff, heavy meehanite machine base to provide vibration dampening + spindle construction with high quality ceramic bearings

- Extensive part diameter range: Large work envelope with generous axes travels

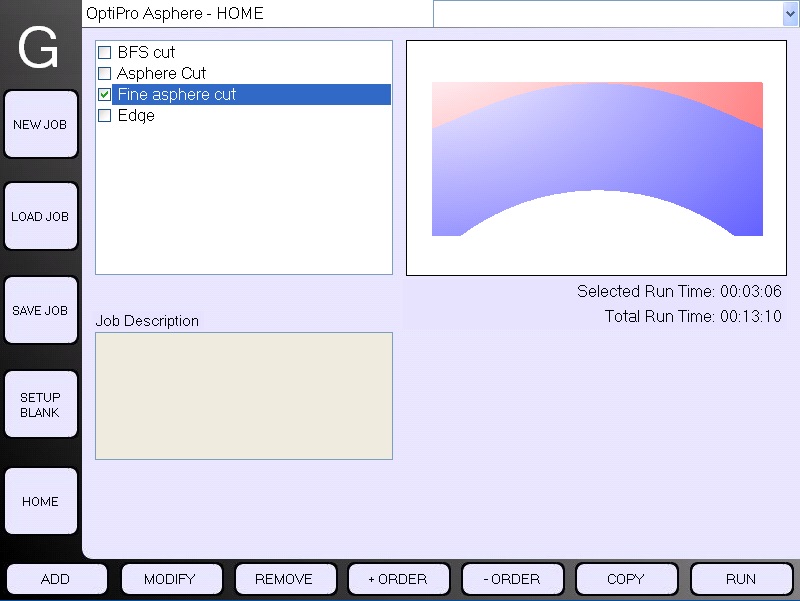

- Faster set ups: Easy-to-use Graphical User Interface for precision optics with step-by-step process driven software (G Series)

- Full 5-axis machining standard: Capable of CAM driven manufacturing of off-axis, non-rotationally symmetric parts as well as coring operations

- High accuracy tool and work spindles: HSK 63 quick-change holders for less chatter

- Process consistency: Liquid cooled spindles

- Better process control: Direct drive spindles

- More cutting power: Integral high torque spindle motor

- Tooling flexibility: Accommodates a wide variety of tools, including ball tools

- Energy efficient: Servos turn off automatically

- Additional features available: Automatic tool and work piece probes, twin spindles, automatic tool changers, mist removal, and more

Maximize throughput of precision optics by implementing the capability of the eSX 400 into your manufacturing operations.

-

Specs

eSX 400 Technical Specifications

Optical Grinding Machine Specs* eSX 300 eSX 400 SXL 500 Workpiece Optimal Dia. Range 5-300 mm (.2-11.8") 5-400 mm (.2-15.7") 10-500 mm (.4-19.6") Max. Plano Diameter** 350 mm (13.8") 450 mm (17.7") 550 mm (21.7") Max. Weight 129 kg (285 lbs.) 154 kg (340 lbs.) 154 kg (340 lbs.) Work Spindle Spindle Speed 0-250 RPM 0-200 RPM 0-200 RPM Hydro Expansion Chuck Standard Standard Standard C-Axis Position and Hold Standard Standard Standard Tool Spindle Maximum Tool Diameter 250 mm (9.8") 250 mm (9.8") 300 mm (11.8") Maximum Tool Weight 6 kg (13.2 lbs.) 6 kg (13.2 lbs.) 6 kg (13.2 lbs.) Tool Spindle Speed 1,000-18,000 RPM 1,000-18,000 RPM 1,000-12,000 RPM Spindle Power (Peak) 18kW (24.1hp) 18kW (24.1hp) 18kW (24.1hp) Tool Holder Style HSK63F HSK63F HSK63F Coolant Thru Spindle Optional Optional Optional Twin Spindle Optional N/A N/A Travels X-Axis Travel 500 mm (19.6") 500 mm (19.6") 1,200 mm (47.2") Y-Axis Travel 400 mm (15.7") 400 mm (15.7") 700 mm (27.6") Z-Axis Travel 500 mm (19.6") 500 mm (19.6") 500 mm (19.6") B-Axis Travel -90° to 90° -90° to 90° -90° to 90° C-Axis Travel 0° to 360° 0° to 360° 0° to 360° Communication Interface Ethernet Standard Standard Standard USB Standard Standard Standard Automatic Tool Changer Optional Optional Optional Machine Dimensions Width 2,110 mm (83") 2,110 mm (83") 2,570 mm (101") Depth 2,515 mm (99") 2,515 mm (99") 3,700 mm (146") Height 2,700 mm (106") 2,700 mm (106") 3,020 mm (119") Weight 3,400 kg (7,500 lbs) 3,400 kg (7,500 lbs) 5,750 kg (12,650 lbs) Workpiece Probing Standard Standard Standard Tool Probing Standard Standard Standard Integrated Spherometer Optional Optional Optional Asphere Fabrication Optional Optional Optional Freeform Fabrication Optional Optional Optional * Specifications subject to change. Contact OptiPro for the latest specifications.

** Machine is capable of manufacturing maximum plano size in small volume. For medium and large production quantities of max plano size, consider OptiPro’s larger platform.

Machine Features

- 5 controllable axes: X, Y, Z, B & C with up to 5 axes of simultaneous movement

- Fagor 8065 CNC machine control with a high resolution LCD touch screen monitor and enhanced contouring package

- Automatic tool probe and work probe for in-process monitoring

- Menu-driven data entry screens with operator prompts for process data input minimizes set-up time

- Graphical tool path verification increases safety by allowing operator to visualize the grinding operation step-by-step before actually running the part

- Quick tool change and precision tool registration with the use of industry standard tapered tool holders

- Continuous display of axes positions and distance-to-go values

- Automatic curve correction using spherometer radius measurement input

- Optional Equipment

Coolant through tool spindle

- Mist removal

- Automatic tool changer

- Built in handheld spherometer

- Coolant filtration system

- Asphere process & analysis software

-

Video