OptiSonic 1100 Series Extended Ultrasonic Machining Centers with 1100mm of X-Axis Travel

-

Overview

OptiSonic 1100 Series Overview

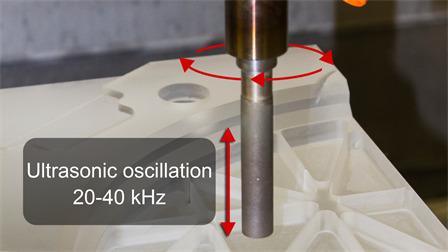

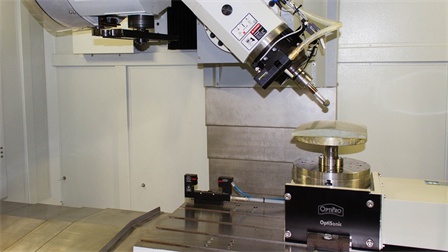

The OptiSonic 1100 Series Ultrasonic Machining Centers combines the quality and precision of OptiPro’s optical grinding machines with the latest Ultrasonic technology in an extended platform that provides 1100mm of X-axis travel. The 1100 Series, which includes four different platform configurations, utilizes Ultrasonic vibration during the machining cycle to accomplish rapid material removal, improved surface quality, and maximized tool life when processing soft optical glass such as BK7 and Zerodur or difficult-to-machine hard ceramics including PCA and sapphire.

Multiple advanced features and capabilities of the OptiSonic 1100 Series allow manufacturing companies to achieve unprecedented machining efficiency:

- Better grinding: Stiff, heavy meehanite machine base to provide vibration dampening + spindle construction with high quality ceramic bearings

- Faster cycle times: State-of-the-art ultrasonic technology allows for faster speeds and feeds than competitive platforms

- Extensive part diameter range: Large work envelope to accommodate part sizes up to 1,075mm x 575mm

- Multiple axis configurations available: Choose from 3 axes (OptiSonic 1130), 4 axes (OptiSonic 1140), or 5 axes (OptiSonic 1150) depending on your application requirements

- Full 5-axis machining (optional): Available with G Series (OptiSonic 1150X) for fast setups when grinding spheres and aspheres, as well as CAM driven milling, cutting, and contouring of off-axis, non-rotationally symmetric parts such as aspheric cylinders and freeforms

- Platform flexibility: Can be configured with an optional C-Axis or an A-Axis, depending on your application requirements.

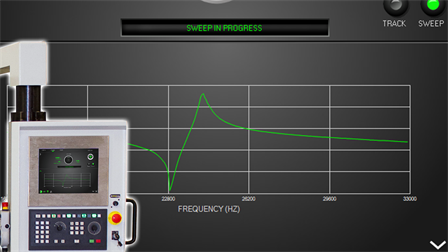

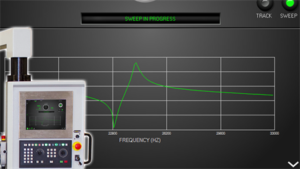

- Predictable results: Proprietary IntelliSonic software automatically adjusts ultrasonic frequency during cycle, ensuring ultrasonic efficiency stays constant

- Process consistency: Liquid cooled spindles

- Better process control: Direct drive spindles

- More cutting power: Integral high torque spindle motor

- High accuracy tool and work spindles: HSK 63 quick-change holders with heat shrink system ensures tools run true

- Streamlined manufacturing: Different Automatic Tool Changer configurations available allows multiple grinding operations in one cycle

- Coolant-through spindle standard

- Tool and workpiece probing standard, including laser tool probe

Whether your application involves 3-axis operations (lightweighting, pocketing, core drilling, small hole manufacturing, rastering, deep drilling, etc.) or more complex geometries that require 4 or 5 axes, you can maximize throughput and quality of glass and ceramic components. Revolutionize your company’s machining capabilities with the OptiSonic 1100 Series.

-

Specs

OptiSonic 1100 Series Technical Specifications

Machine Specifications* OptiSonic 1130 OptiSonic 1140 OptiSonic 1150 OptiSonic 1150X Travels X-Axis Travel 1100 mm (43.3") 1100 mm (43.3") 1100 mm (43.3") 1100 mm (43.3") Y-Axis Travel 600 mm (23.6") 600 mm (23.6") 600 mm (23.6") 600 mm (23.6") Z-Axis Travel 800 mm (31.5") 800 mm (31.5") 800 mm (31.5") 800 mm (31.5") B-Axis Travel N/A -90° to 90° (Optional) -90° to 90° -90° to 90° C-Axis Travel N/A 0° to 360° (Optional) 0° to 360° 0° to 360° Workpiece Part Size 1,075 mm x 575 mm (42.3" x 22.6") 1,075 mm x 575 mm (42.3" x 22.6") 1,075 mm x 575 mm (42.3" x 22.6") 10-500mm (.4- 19.6") Max. Plano Diameter** N/A N/A N/A 550mm (21.7") Max. Weight 800 kg (1,763.7 lbs.) 350 kg (770 lbs.) 350 kg (770 lbs.) 154 kg (340 lbs.) Workpiece Rotation Positional C-Axis Positional C-Axis Work Spindle Spindle Speed N/A N/A N/A 0-200 RPM Hydro-Expansion Chuck Optional Standard Standard Standard C-Axis Position and Hold N/A Standard Standard Standard Tool Spindle Maximum Tool Diameter*** 250 mm (9.8") 250 mm (9.8") 250 mm (9.8") 250 mm (9.8") Maximum Tool Weight 6 kg (13.2 lbs.) 6 kg (13.2 lbs.) 6 kg (13.2 lbs.) 6 kg (13.2 lbs.) Tool Spindle Speed 1,000-18,000 RPM 1,000-18,000 RPM 1,000-18,000 RPM 1,000-18,000 RPM Maximum Power 18kW (24hp) 18kW (24hp) 18kW (24hp) 18kW (24hp) Tool Holder Style HSK63F HSK63F HSK63F HSK63F Coolant Through Spindle Standard Standard Standard Standard Automatic Tool Changer 30-tool Swing-Arm (Optional) 30-tool Swing-Arm (Optional) 30-tool Swing-Arm (Optional) 30-tool Swing-Arm (Optional) Workpiece Probing Standard Standard Standard Standard Tool Probing Standard Standard Standard Standard Integrated Spherometer N/A N/A N/A Optional Asphere Fabrication N/A N/A N/A Optional Freeform Fabrication N/A Optional Optional Optional *Specifications subject to change. Contact OptiPro for the latest specifications.

**Machine is capable of manufacturing maximum plano size in small volume. For medium and large production quantities of max plano size, consider OptiPro’s larger platform.

***Max tool diameter is 75mm (3″) with a full Automatic Tool Changer magazine.

All platforms come standard with USB and ethernet communication.

-

Video