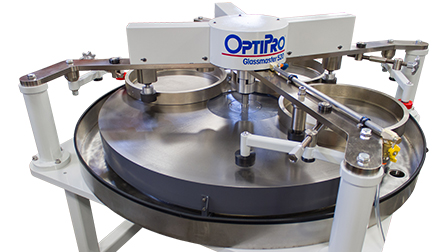

Glassmaster 520 Continuous Planetary Polisher

-

Overview

Glassmaster 520 Overview

The Glassmaster 520 is a state-of-the-art continuous planetary polisher (CP) that incorporates patented technology to deliver exceptional flatness and finish of flat optical components.

Multiple valuable features on the Glassmaster 520 allow companies fabricating flat optics to maximize throughput and their bottom line:

- Patented Syncroshaft drive system

- Glassmaster 520 and its 52 inch table is competitively priced and offers 4 more inches in diameter of the work surface

- Accepts 12 to 23 inch diameter carrier rings

- State-of-the-art programmable AC motor controls

- Robust oil bath drive line

- Heavy duty zero stress, zero flex polishing table

- Self cleaning stainless steel recovery tank

- Smallest machine footprint in the industry

- Super tough powder coat painted finish

- Built with industry-standard components

- Less than one tenth of 1% worldwide down time

- Easiest and widest range of carrier ring adjustments in the industry

- 1 year warranty

Whether your application involves glass, ceramic, silicon, crystal, or metal plano optics, the Glassmaster 520’s unmatched efficiency and precision will help your company become more productive and profitable.

-

Specs

Glassmaster 520 Technical Specifications

Planetary Polishing Machine Specifications Glassmaster 520 Total Height 57 in. Length 60.5 in. Width 60.5 in. Weight 4,750 lbs. Table Height 37 in. Table OD 52 in. Table ID 14 in. Table Material Cast iron Motor Type 3PH continuous duty H.P. 3 (5) Motor Controls AC inverter - NEMA4 Input Voltage 230V3PH (480V3PH) Primary Gear Box Worm gear 10:1 Secondary Gear Box Torque arm reducer 25:1 Table RPM Range 0-7 (0-14) Recommended Conditioner Diameter 26 in. Maximum Conditioner Height 4.5 in. Carrier Ring OD 20.5 in. Carrier Ring ID 19 in. Number of Carrier Rings 3 * Specifications subject to change. Contact OptiPro for the latest specifications.

** Specs for Glassmaster High Speed version in parentheses. -

Benefits

Glassmaster 520 Benefits

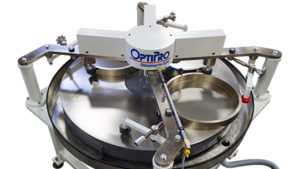

The Syncroshaft Advantage

The patented Syncroshaft carrier ring drive system accurately synchronizes the rotation of all three carrier rings, ensuring consistent flatness and finish between all work stations. This is accomplished by utilizing the rotating motion of the polishing table to drive the workstation carriers. The design is extremely straightforward and dependable, eliminating the cumbersome controls, wiring and motors that commonly fail on conventional carrier drive systems. The Syncroshaft system is designed to be virtually maintenance free.

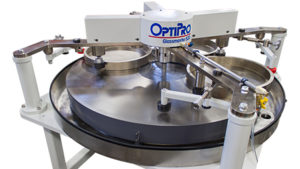

Superior Table Design

The Glassmaster 520’s polishing table sets an industry standard for rigidity and stability. Consistent flatness tests of 1/20 to 1/30 of a wave length can be expected. Made of high-grade stress-relieved gray cast iron, the Glassmaster 520’s one-piece polishing table weighs in at over 2,000 pounds. Strategically placed reinforcements on the underside of the table in conjunction with a one-inch thick cast outer drip edge ensures maximum rigidity and zero flex. The table rides on a heavy duty, 26 inch diameter angular contact bearing, providing smooth and precise table rotation and lasting durability. A polished stainless steel recovery tank surrounds the whole arrangement, neatly guiding the polishing solution back to the steel reservoir and effectively protecting the table bearing from dirt and moisture.

Robust Drive Components and State-of-the-Art Controls

The polishing table and syncroshaft system are powered by a heavy duty, three-horse power AC motor that drives two highly durable oil bath gear boxes. Together, they produce over 30,000 inch pounds of table torque, allowing for extremely heavy workloads to be polished. The drive motor is controlled by a user-friendly, fully programmable AC power inverter, which has the capability of operating on 230 volts three phase electrical power.

Motor control features include:

- Variable speed control

- Preset speed

- Ramp start

- Motor load

- Full LED readout

- Forward and reverse jog

The Glassmaster 520’s open air power drive compartment enhances cooling, allows for easy component inspection and simplifies lubrication maintenance tasks. The motor controls are state-of-the-art. All the components in the power drive system are specified at two and a half times the normally calculated service factor required to drive the machine, allowing it to be operated 24 hours a day on a continuous basis.

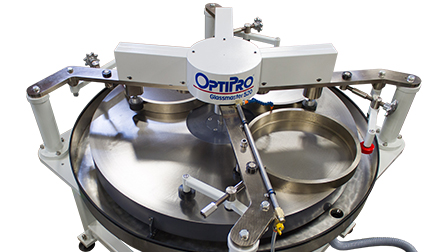

High Versatility Work Station

Because of Glassmaster 520’s unique work station design, there is no vertical obstruction over the carrier rings, allowing work of any height to be polished. Each carrier ring position is adjusted by a threaded scissor assembly, which allows quick and easy carrier movement without reaching over the polishing table. This feature greatly reduces the possibility of contaminating the polishing surface or slurry solution.

Each work station accepts carrier rings ranging from 12-23 inches diameter. Carrier ring positions are quickly and easily adjusted by simply turning a handwheel.