Machine Tool Showroom

OptiPro Systems state-of-the-art 15,200 square-foot Machine Technology Center is stocked with the latest machine tools and manufacturing technology. Whether you are looking for high performance machining centers, turning centers, multi-tasking machines, wire EDM’s, or waterjet technology, stop by our showroom for a demonstration to see how you can enhance your manufacturing capabilities.

Currently in our Showroom (click on any of the below for details and product brochures)

Fanuc Robocut C400iC Wire EDM - Newly design and upgraded FANUC EDM

- X axis Travel 15.75″ (400mm)

- Y axis Travel 11.8″ (300mm)

- Z axis Travel 10.0″ (255mm)

- Newly design and improved automatic wire feed (AWF)

- Standard Wire Diameter .004″ – .0012″

- Inverted X and Y axis

- Upgraded graphics processor

- Improved simple adjust function

- new simple corner control adjust

- New undo/redo function

- Pinch zoom capable

- Improved guidance screen

View Product Brochure

FANUC Robodrill α-D21SiB5 Series Short Bed - Compact Vertical Machining Center capable of high speed, high precision and high-efficiency operation

X axis Travel 11.8″ (300 mm)

X axis Travel 11.8″ (300 mm)- Y axis Travel 11.8″ (300 mm)

- Z axis Travel 13″ (330)

- Table Load Capacity: 440 lbs (200 kg)

- Machine Weight: 4740 lbs (2150 kg)

- 21 Tools

- 24K RPM

- Fanuc 31i-B5 Control

View Product Brochure

FANUC Robodrill α-D21LiB5 ADV Series Long Bed - Compact Vertical Machining Center capable of high speed, high precision and high-efficiency operation

- High performance machining center

- FANUC 31iB 5-axis control for the ultimate in machine processing, is loaded with standard features exclusive to Robodrill

- Three models to choose from: SHORT, MEDIUM and LONG bed 10K or 24K Big Plus 30-taper spindle rpm available

- Robodrill’s carousel style, fast and reliable automativ tool changers has only 4 moving parts

- Automation ready: the Robodrill is perfectly suited for long unattended operation

- FANUC DDR High Speed Direct Drive 4th axis and DDRT (Trunion Style) is available as an optional feature

View Product Brochure

SOLD: Nakamura-Tome AS200LMYS - Subspindle machine, a high-performance multitasking turning center

- Space Saving Combined Machine Tool with Y-axis & Milling Function (standard)

- With Y-axis! Stroke: 82mm

- With Milling Function: 7.5/5 HP, Spindle Speed: 6000rpm

- Strong Spindle Motor: 20/15 HP

- High Speed Index! X-axis: 24m/min, Z-axis: 36m/min, C-axis: 600min-1

- Turret: Max Dodecagonal Drum Turret (Max. 24 station)

- Number of Milling Tool (dodecagonal drum turret): 12

View Product Brochure

Methods MB450 Simultaneous - 5-Axis Bridge Type Machining Center

- 15,000 RPM BIG-PLUS, 40 Taper Spindle

- Direct Drive Hollow Shaft Spindle Motor

- Robust Bridge Type Construction with Thermal Compensation

- Tool Center Point Control

- Collision Detection

- Large Capacity 48 Tool ATC

- Includes Scales in All Axes & Kinematic Calibration Hardware/Software

View Product Brochure

Methods MV1000L - Vertical Machining Center combined with high-end features

- FANUC 0i-MF Plus Control

- Linear rail-type guideways in the X/Y/Z axes

- Thermal Compensation

- 19 hand-scraped surfaces

- 12,000 RPM BIG-PLUS, 40 Taper Spindle

- 30 Tool ATC

View Product Brochure

Hyundai Wia KF5600 High Speed Machining Center - Designed with advanced technology, fast & versatile machining center that maximizes productivity

- Diverse spindle structure (direct-connection: 8K, 12K; built-in: 15K, 20K)

- Increases strength through structural analysis

- Expands machining domain with y-axis 560mm design

- Shortens not-cutting time with rapid feeds (40/40/36m/min.)

- Mould packages for optimum mould manufacturing (20K built-in)

- Applied the latest HEIDENHAIN TNC 620 controller

View Product Brochure

Hyundai Wia SE2200LSYA Multi-Tasking Y Axis Turning Center - Long lasting, high accuracy and excellent performance CNC Turning Center

- 30° slanted one-piece bed structure with high rigidity

- Stabilized unit structure to minimize thermal displacement

- Integrated processing through synchronized control of Main/Sub spindle

- Multi-tasking operation with wedge type Y-axis BMT45 turret

- Excellent rapid traverse rate (X/Y/Z) : 30/10/36 m/min (1,181/394/1,417 ipm)

- Ergonomic design for convenient access to chuck and tool

- X/Y/Z Travel: 8.3/4.3/22 in (210/110/560) mm

View Product Brochure

Hyundai Wia LV 8500L - High Productivity, Heavy Duty Vertical Turning Center

Swistek SV26-Y2 1-inch Automatic Screw Machine

- 5 Cross Live Tools on main spindle

- Pre-tensioned ball screws and THK linear guideways

- Loaded FANUC 32i Control, Dual Path Control

- Festo pneumatic valves and pneumatic cylinders from Germany

- Can run in swiss or chucking mode

Dynapath VK-3T Knee Mill

- DynaPath Delta 2000M CNC Control with Standard Features, 12″ Color LCD

- Cast Iron Bed with Hardened and Ground Slide Ways

- Flood Coolant System

- Auto Lubrication System

- Halogen Work Light

- Telescoping Way Covers

- Work Table 10 x 50″

- X-Y-Z Travel (in): 31″ x 14.5″ x 5″

- Rapid feed 250 ipm

- Weight (approx.) 3100 lbs

View Product Brochure

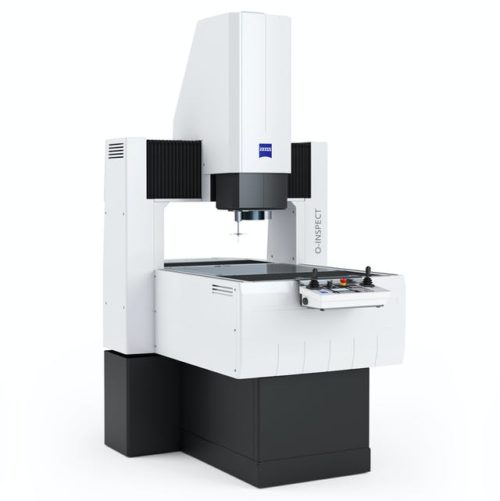

ZEISS O-INSPECT 543 - Multisensor measuring machine with DotScan and Rotary

- Telecentric zoomlens Discovery

- Adaptive illumination system

- Scanning sensor ZEISS VAST XXT

- Probing rack

- Calibration sphere

View Product Brochure

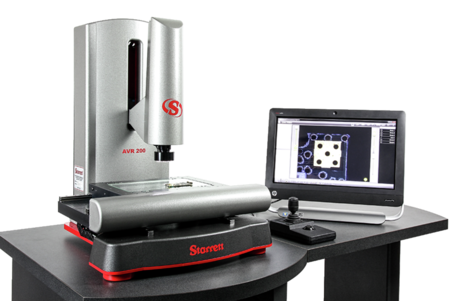

Starrett AVR200 6LED , State-of-the-art AVR CNC Vision System featuring 6-Channel LED Illumination

- X-Y-Z Travel (in): 8” x 4” X 8”

- X-Y Accuracy: E2 = 1.9 µm + 5L/1000

- Z Accuracy: E1 = 2.5 µm + 5L/1000

- Scale Resolution: 0.1 µm

- Control/ System; Metlogix M3

- Display: 4” Touchscreen Monitor

Starrett HDV400 - Horizontal Vision System, combining the capabilities of both a horizontal optical comparator and a vision metrology system

- X-Y-Z Travel (in): 16″ x 6″

- X-Y Accuracy (µm): E1 = 3.0 µm + L/33

- Scale Resolution: 0.5 µm

- Control System / Software: M3

- Display: 24″ Touchscreen Monitor

- Video Edge Detection

Starrett FMM-550 - Digital Force Tester optimized for production and quality control testing

- Vertical Test Space: 22in

- Travel – Position Accuracy: +/-0.001” or 0.1% of displacement whichever is greater

- Travel – Resolution: .001in

- Speed – Minimum: .002in/min

- Speed – Maximum: 40in/min

- Speed – Maximum @ Full Capacity: 40in/min

- Speed – Accuarcy: Better than 0.1% of test speed

- Cycling – Maximum Number: Counts 99,999

- Cycling – Maximum Duration: 27 hours

- Load Hold – Maximum Duration: 27 hours