Custom Automation Solutions

-

Overview

Custom Automation Solutions Overview

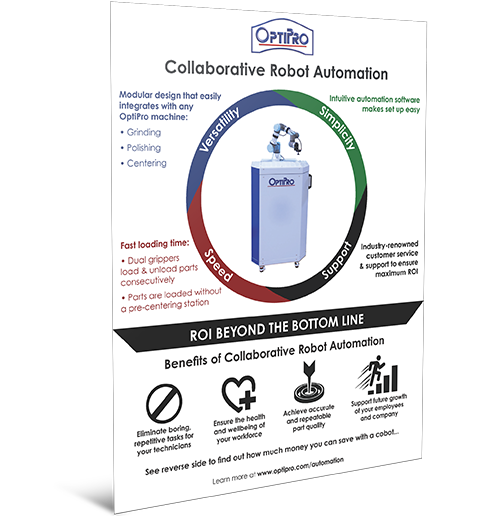

Robot automation has become increasingly popular in manufacturing due to the numerous benefits it offers, including improved efficiency, safety, consistency, cost savings, flexibility, and data collection. OptiPro has extensive experience working with companies to add automation to their manufacturing operations. Some of the custom automation projects we have successfully engineered range from multi-machine production cells to automated part inspection solutions:

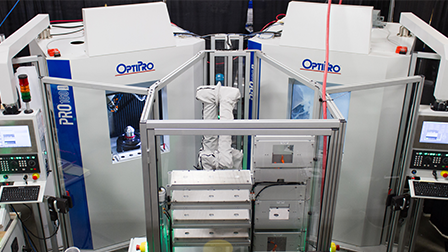

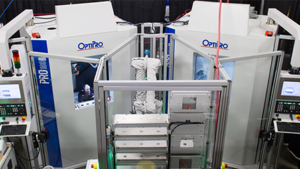

- Two-machine automation cell with Pro 160 GTS generator, PRO 160P high speed spherical polisher, and wash and dry system. Excess swarf and coolant is rinsed off the part after it is generated to avoid contaminating the polisher. After the polishing cycle, the part is washed and dried then loaded on the pallet. The robot moves the part between the machines, simultaneously loading and unloading parts after grinding and polishing.

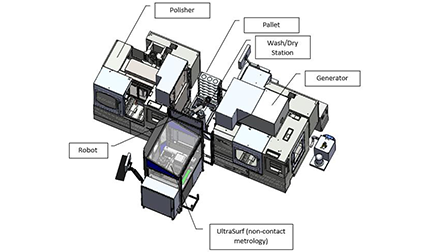

- Three-machine automation cell with eSX 400 optical generator, a CNC optical polisher, an UltraSurf 4X 300 non-contact metrology system, and a wash and dry station. With this solution, the part, after being ground and polished, is measured on the UltraSurf to determine if it is in spec or not in spec. If it is not in spec, the computer calculates a correction and the robot returns the part to the polisher.

- Automated part inspection with the ZEISS O-Inspect 543 multisensor CMM. The robot picks up the part and places it on a universal vacuum fixture on the O-Inspect, where it is measured with a probe and high contrast imaging. After the measurements are analyzed by ZEISS Calypso software, the robot places the part on either a “Good” or “Bad” tray based on measurement results communicated to the robot.

By adopting robot automation, manufacturers can increase their competitiveness in the global market and improve their bottom line. If you have a process you are looking to automate, let OptiPro’s expertise help make your concept a reality.

-

Video