Proprietary IntelliSonic™ software with adaptive control ensures optimal ultrasonic grinding conditions

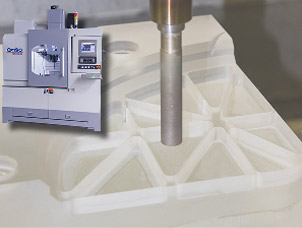

Ontario, NY, August 14, 2014 – OptiPro Systems, LLC, designer and manufacturer of precision optics fabrication equipment, has revolutionized ultrasonic machining technology by introducing a new solution to achieve unprecedented grinding efficiency on both hard and soft optical materials. The OptiSonic machine combines the capability of OptiPro’s current optical grinding platforms with proprietary IntelliSonic™ software produce several key benefits. Ultrasonic vibration during the grinding cycle allows rapid material removal and reduced cycle times. Tool wear, an issue that escalates dramatically with hard optical materials such as sapphire and spinel, is greatly reduced with OptiSonic. In addition, improved surface quality is attained after grinding both hard materials and softer glasses including BK7 and Fused Silica.

Ontario, NY, August 14, 2014 – OptiPro Systems, LLC, designer and manufacturer of precision optics fabrication equipment, has revolutionized ultrasonic machining technology by introducing a new solution to achieve unprecedented grinding efficiency on both hard and soft optical materials. The OptiSonic machine combines the capability of OptiPro’s current optical grinding platforms with proprietary IntelliSonic™ software produce several key benefits. Ultrasonic vibration during the grinding cycle allows rapid material removal and reduced cycle times. Tool wear, an issue that escalates dramatically with hard optical materials such as sapphire and spinel, is greatly reduced with OptiSonic. In addition, improved surface quality is attained after grinding both hard materials and softer glasses including BK7 and Fused Silica.

The most notable feature of IntelliSonic™ is its ability to maintain the highest cutting efficiency through adaptive power and frequency tracking during the machining cycle. “What sets OptiSonic apart from the competition is the impressive capability of the IntelliSonic™ Software,” said Mike Bechtold, President of OptiPro Systems. “When you integrate this technology into a robust platform that consists of only the highest quality machine components, you get a solution that can overcome the challenges associated with grinding moderate to extremely hard optical materials.”

OptiSonic takes advantage of the rigidity and precision of heat shrink tool holding, allowing operators to quickly change tools from the holder. Once returned to the spindle, the holder can be re-tuned for the new tool automatically. Other features and options of the OptiSonic include a full CNC control with a powerfully simple graphical user interface, automatic tool changer, coolant-through spindle, workpiece and tool probing, and much more.

OptiSonic is available in multiple configurations: OptiSonic 3X allows for 3-axis movement (X, Y, Z) perfect for pocketing, core drilling, light weighting, edging, and rastering. OptiSonic 5X has up to 5-axes of simultaneous movement (X, Y, Z, B, C) and adds the capability to cut and contour more complex shapes as well as perform truncations. With IntelliSonic™ technology, OptiSonic is an ideal fit for companies looking to decrease cycle times and improve surface quality of soft to hard optical materials.

About OptiPro:

OptiPro Systems, LLC is the only U.S. company that designs and builds CNC optical grinding, high speed spherical polishing, sub-aperture polishing, and metrology equipment. OptiPro started out as a reseller and service provider for CNC metalworking equipment over 30 years ago and evolved into an original equipment manufacturer (OEM) of an extensive line of machines for precision optics fabrication.

Press contact:

Pat Bechtold, Marketing Coordinator

OptiPro Systems

Phone: 585.265.0160 x-235

Email: pbechtold@optipro.com