Precision optics made from infrared materials have a multitude of applications across various industries due to their unique properties and capabilities. Infrared (IR) optics refer to optical components designed to operate in the infrared spectrum, typically beyond the range of visible light. Some key applications of precision IR optics include thermal imaging, night vision, remote sensing, medical imaging, industrial inspection, and laser systems.

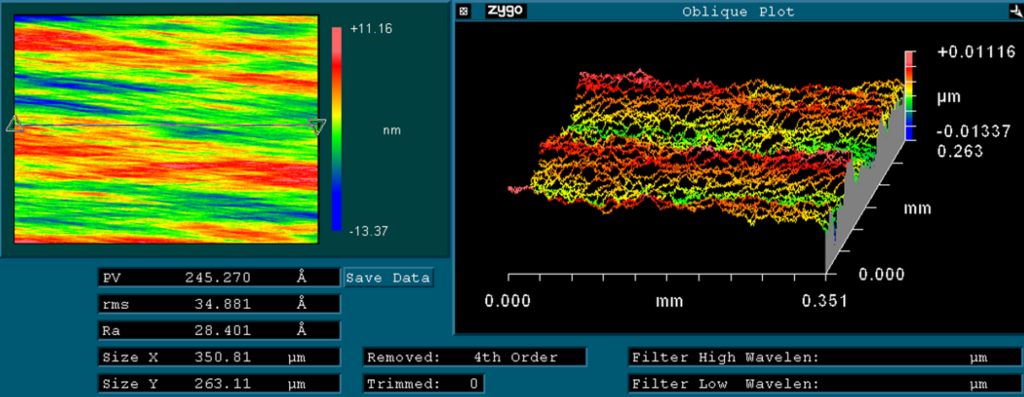

Depending on the optical assembly, surface quality of each optic plays a critical role in the overall performance of the system in which they reside. Germanium (Ge) is common IR material that has various uses, including aerospace and defense applications. UltraForm® Finishing (UFF™), OptiPro’s patented sub-aperture optical polishing process, enables optical manufacturers to produce Germanium optics with precision-level surface quality specifications. The metrology data below shows typical roughness and surface quality that can be achieved when polishing Germanium optics with UFF™. Although this testing was performed on flat optics, the process to reach these specifications is transferable to spherical optics and aspheres as well.

Depending on the optical assembly, surface quality of each optic plays a critical role in the overall performance of the system in which they reside. Germanium (Ge) is common IR material that has various uses, including aerospace and defense applications. UltraForm® Finishing (UFF™), OptiPro’s patented sub-aperture optical polishing process, enables optical manufacturers to produce Germanium optics with precision-level surface quality specifications. The metrology data below shows typical roughness and surface quality that can be achieved when polishing Germanium optics with UFF™. Although this testing was performed on flat optics, the process to reach these specifications is transferable to spherical optics and aspheres as well.

Process

Before analyzing the metrology data, here is a brief overview of the process to achieve precision-level Germanium optics:

- CNC optical grinding of surface using rough (D46) and fine (D15) ring tools

- “Rough” polishing of surface with UFF™ using a 3um abrasive belt and coolant

- Precision polishing of surface with UFF™ using a LP 46 polyurethane belt and Baikalox® polishing slurry

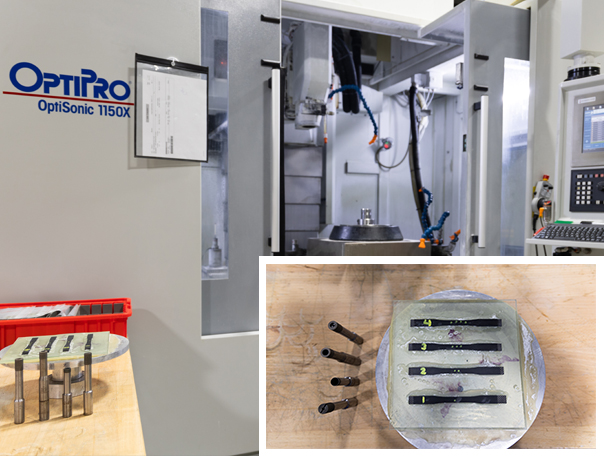

The PRO 80 GTS was utilized for CNC optical grinding, while the PRO 80 UFF performed polishing of the Germanium surface.

Metrology Results

As shown in the Zygo NewView™ metrology image above, optical manufacturers can anticipate surface roughness of <50Å RMS. In addition, cosmetics of 60/40 scratch-dig are also obtainable by using UFF in your Germanium optics manufacturing process.

UltraForm® Finishing has demonstrated the capability of achieving precision surface quality specifications for IR optics, especially Germanium. Similar surface roughness and cosmetics can also be expected for Silicon (Si) optics, as this IR material is comparable to Germanium. If you are looking to improve your IR optics manufacturing process, contact OptiPro today and let us collaborate with you on your next project.