ZEISS O-INSPECT Multisensor CMM

100 YEARS OF INDUSTRIAL METROLOGY

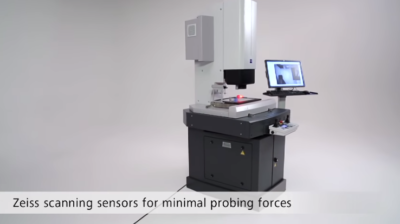

Complex measurements can be performed quickly and easily with optical measuring solutions from ZEISS. With a high degree of automation and state-of-the-art sensors, they reduce operating errors and guarantee high measuring accuracy.

The ZEISS O-INSPECT multi-sensor coordinate measuring machine provides the perfect combination of both optical and contact scanning results. With the capability to automatically change sensor types, this allows the operator flexibility to measure different features of a complex part on the same machine all from a single set up. The process reduces time to measure, multiple set ups and the need for an optical and contact measuring machine.

Across all industries, the ZEISS O-INSPECT Multi-sensor CMM proves valuable. From companies who produce blades for turbine engines to those creating artificial hips and joints, the benefits are obvious. Medical companies producing artificial joints for the human body need to make sure that the piece is measured exactly to fit the patient. With complex geometries of each piece, multiple sensors would be required as well as more than one machine. The versatility and capability of the ZEISS O-INSPECT can examine each device and improve the throughput and accuracy of your inspection process.

The software platform is what also provides the ease of use with the CMM. CALYPSO software provides an interface to statistic software allowing you as the customer to archive measurement data. Our team at OptiPro provides training on CALYPSO software for ZEISS O-INSPECT & O-SELECT.

ZEISS O-INSPECT FAMILY

O-INSPECT 322: Measuring range [dm] 3/2/2; O-INSPECT 543: Measuring range [dm] 5/4/3;

O-INSPECT 863: Measuring range [dm] 8/6/3