Automated defect and feature metrology system enables new levels of quality and reduced rework for aerospace components further enabling aviation safety standards.

From left to right: Erik Novak – VP and GM at 4D Technology, Mitchell Sedore – Head Automation Engineer at OptiPro Systems, Mike Cicco – President & CEO at FANUC America

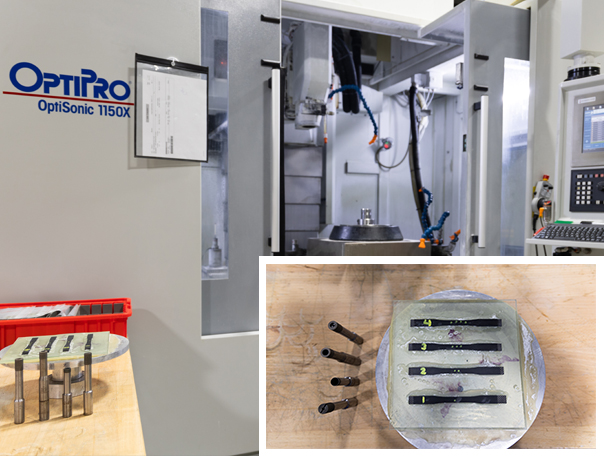

Ontario, NY – February 29, 2024 – OptiPro Systems, LLC, a FANUC Authorized Systems Integrator (ASI) and leading manufacturer and distributor of precision CNC machines and CAD/CAM software, has announced that they have been named winner of FANUC America’s 2024 Innovative System of the Year award for the 4Di InSpec automated metrology system (AMS). In partnership with 4D Technology, OptiPro developed the high-throughput, high resolution defect and feature inspection solution. A FANUC collaborative robot and custom metrology automation software developed by OptiPro enables the system to measure dozens of edge break features, chamfers, and radii in minutes rather than days. By implementing this solution, a manual operation that took multiple weeks to make 400 measurements was reduced to a matter of minutes.

“This award is a reflection of the incredible automation team we have at OptiPro,” said Rob Bechtold, President of OptiPro Systems. “As a FANUC Authorized Systems Integrator, OptiPro is dedicated to providing robotic automation solutions that help manufacturing companies achieve new levels of excellence. This robotic solution is a prime example of our ability to collaborate with manufacturers looking to automate processes that lead to more efficient production.”

The automated metrology system can be configured for multiple applications, including large, rotary applications, small freeform components such as turbine blades and multi-sensor applications. It is powered by OptiPro’s RoboQual™ custom metrology automation software. RoboQual™ bridges communication between the robot and the measuring device while adding an easy-to-use interface that compiles all measurement data files in one location. After identifying acceptable tolerances during job setup, RoboQual™ analyzes each measurement value and intuitively determines whether the measurement passes or fails. Users can also generate a report from RoboQual™ that contains all measurement data and pass/fail information. The solution is equipped with a FANUC CRX 10iA/L collaborative robot that is easier to program through custom software shortcuts developed by OptiPro’s automation team.

Learn more about OptiPro’s Automation Solutions by visiting www.optipro.com/automation-solutions/.

For more information about the 4Di InSpec automated metrology system, visit the 4D Technology website.