Renishaw Equator

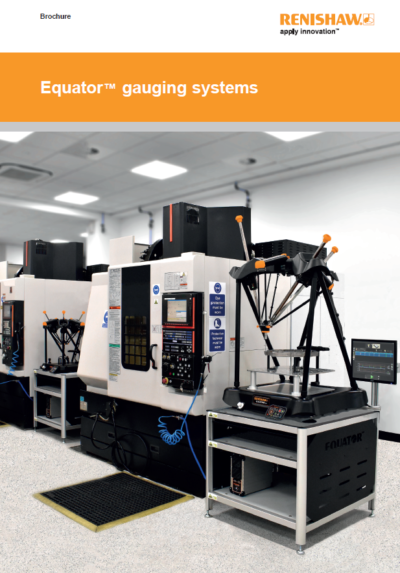

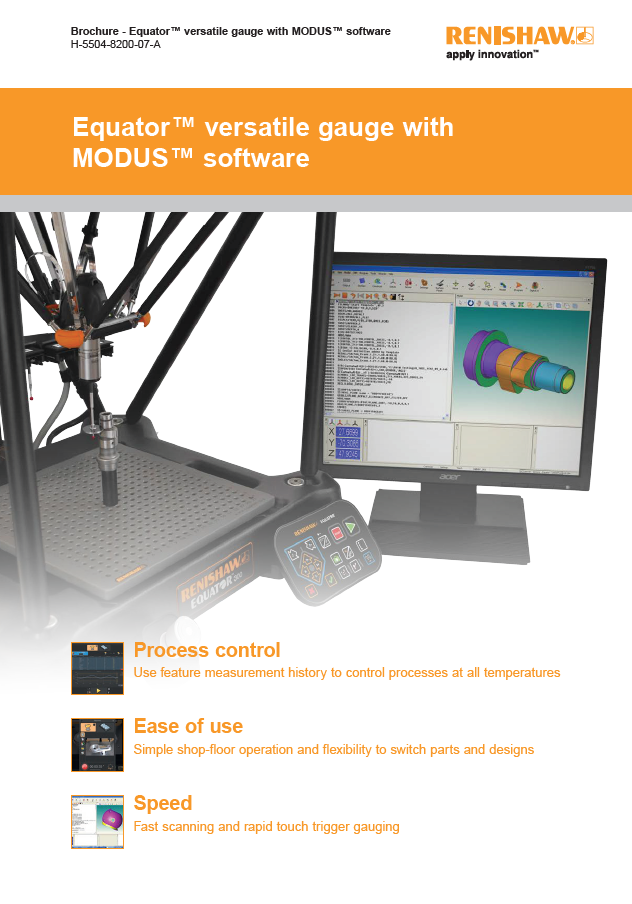

Renishaws’ Equator has proven to be a versatile solution. As an automated gauging system, the benefits are evident within moments of use.

Traditionally, a shop may have a designed quality team that measures a sample batch of work pieces to determine if there are errors. This set up can bottle neck production with pieces waiting to be measured. If your shop tries moving measuring to the floor, the measurements can be distorted by the fluctuating temperature. With the Equator, thermal conditions won’t need to be considered since it is thermally insensitive and can even integrate with automated machining.

With an increasing labor shortage, automation has grown in machine shops to keep up with demand. Integration with the Equator is simple with the equator EZ-IO kit. Check out this Renishaw article that shows how one shop in Texas integrated the Equator Gauging System with their Fanuc Robots.

The benefits also include its versatility and its quick reprogramming. In a design & manufacturing environment, improvements are frequent and new batches constant. With the Renishaw Equator, you can easily transition between new batches and new improvements to pieces. The ease of this transition makes it an indispensable addition to any shop.

Interested in learning more? Our sales team would be happy to assist you with any questions.