Produce precision spheres and aspheres faster with the PRO 80 Series. Built with only the finest machine components and driven by OptiPro’s intuitive software, the PRO 80 GTS, PRO 80P and PRO 80 UFF are ideal solutions for companies looking for efficient setups and cycle times with enhanced accuracy and stability.

What makes OptiPro's PRO 80 Series Better

Reliability and Performance

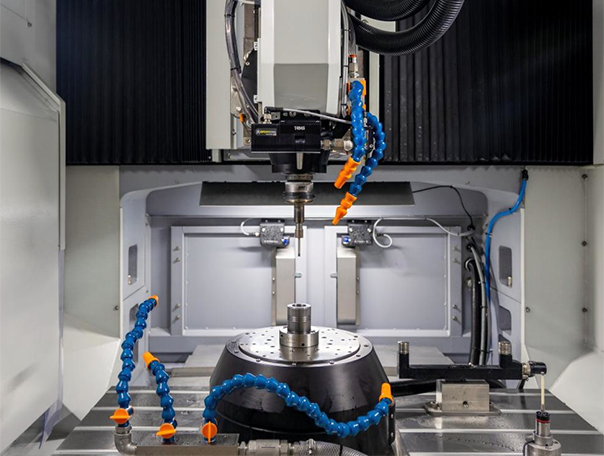

- Process consistency: Liquid cooled air purged, ceramic hybrid tool spindles

- High accuracy: HSK 63 quick-change tool holders provide precision repeatability

- More power: Integral high torque spindle motor, not belt driven

- Smooth travels: Greased-for-life linear guides on all ways of the machine

Compact But Powerful

- Small space requirement: All peripheral equipment is contained within a 40″ by 60″ footprint

- Rock-solid platform: Granite center core ensures ultimate precision and consistent part-to-part accuracy

- Ease of mobility: Retractable wheels for easy movement, leveling feet for fast setup

Convenient Concept

- User friendly GUI: Allows for quick setups and makes training new operators simple and fast

- Ergonomic design: Functional multi-position pendant arm

- Easy to clean: All stainless steel internal enclosure

- Easy to service: Maintenance items readily accessible

From shallow curves to full hemispheres, simple aspheres to radical departures, 5mm to 80mm in diameter, the PRO 80 Series can help your company optimize manufacturing efficiency for precision spherical and aspherical optics. Depending on geometry, you can even produce lenses as small as 1mm and as large as 100mm.

Contact OptiPro to schedule a demo or request a time study for your application and find out how the PRO 80 Series can add significant value to your bottom line.