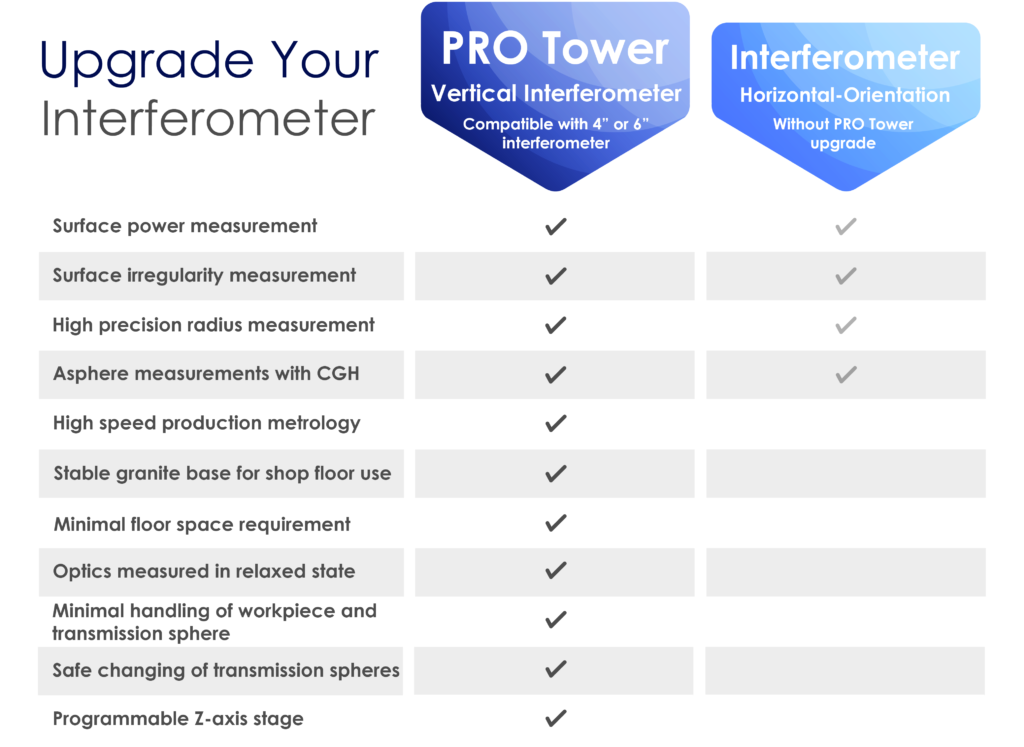

If you measure spherical optics or aspheres with a Fizeau interferometer that is horizontally configured, you could be sacrificing precision, productivity, and safety. Maximize the performance of your laser interferometer by upgrading from a horizontal configuration to a vertical interferometer with the PRO Tower.

If you measure spherical optics or aspheres with a Fizeau interferometer that is horizontally configured, you could be sacrificing precision, productivity, and safety. Maximize the performance of your laser interferometer by upgrading from a horizontal configuration to a vertical interferometer with the PRO Tower.

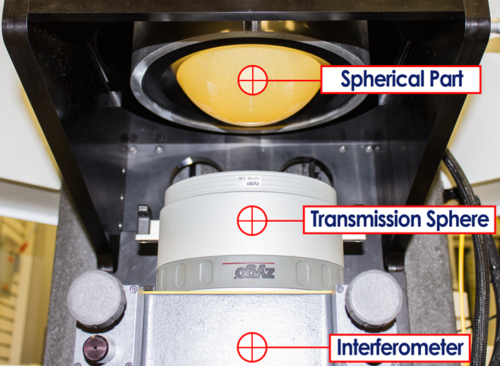

The PRO Tower is a highly stable platform that transforms your existing 4″ or 6″ horizontal interferometer into an upward looking configuration.

There are many significant advantages of vertical interferometry that are non-existent when interferometers are operated horizontally.

Here’s how the two configurations stack up:

Vertical Interferometer Advantages:

High Speed Production Metrology

For jobs with high volume quantities, operator can easily set up the interferometer to null fringes using a master, then place workpieces in and out of the nest of the PRO Tower to quickly measure power and irregularity.

Stable Granite Base for Use on the Shop Floor

Very rigid 4,000 lbs. platform with lab-grade granite core and tripod base with three active isolation pads for stability in a production environment.

Minimal floor space requirement

PRO Tower’s compact vertical configuration saves valuable floor space, compared to horizontal interferometer set up which typically requires an 8 foot isolation table.

Optics Measured in Relaxed State

Highly accurate configuration allows optics to rest safely in a “nest” for stress-free measurements.

Minimal Handling of Workpiece and Transmission Sphere

Once the transmission sphere and workpiece are placed in the PRO Tower, they no longer need to be touched. Measurements are performed by programming the Z-axis stage to move up and down, or by manually jogging the Z-axis stage.

Safe Changing of Transmission Spheres

Ergonomically designed with objective at waist-level, making is easy and safe to change out expensive transmission spheres.

Programmable Z-Axis Stage

By entering the radius of the spherical optic and with the simple click of a button, Z-Axis automatically moves up and down to the distance of the radius entered with 10 nanometer resolution, making it easy to measure radius and irregularity.