C Series Optical Centering Software

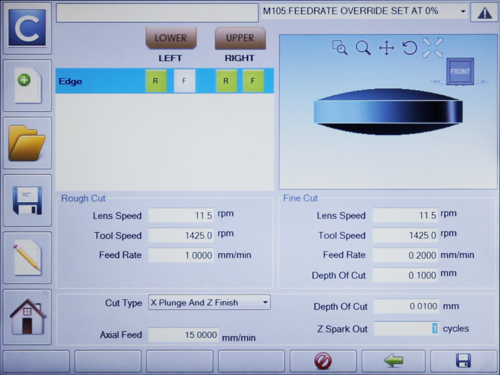

OptiPro Systems’ optical centering software, C Series, allows the operator to perform all common CNC centering processes, including edging, beveling, filleting, sag cuts, and step cuts. C Series has a user-friendly look and feel that takes the operator through clear and concise steps to setup a centering job. Job files store parameters for all the processes required to perform these operations on a given lens. Each process is defined by a series of inputs and parameters including lens geometry, tool parameters, processing parameters, and corrections. A 3D animation preview of the part program displays the wheels and part geometry as you build the program and detects any potential collisions.

OptiPro Systems’ optical centering software, C Series, allows the operator to perform all common CNC centering processes, including edging, beveling, filleting, sag cuts, and step cuts. C Series has a user-friendly look and feel that takes the operator through clear and concise steps to setup a centering job. Job files store parameters for all the processes required to perform these operations on a given lens. Each process is defined by a series of inputs and parameters including lens geometry, tool parameters, processing parameters, and corrections. A 3D animation preview of the part program displays the wheels and part geometry as you build the program and detects any potential collisions.

Features:

Process-Based Job Structure

Each centering job can have a series of processes that are created to produce an optic to the required specifications. These processes can include edging, beveling, filleting, sag cuts, step cuts, tapers and truncations. C Series allows the operator to run multiple processes for the same lens in a single cycle. This capability frees the operator to run multiple machines simultaneously.

Tool Library with Existing Grinding Wheels

C Series allows the operator to enter information for grinding wheels when setting up a job. These tools can be saved in the tool library for any future jobs that would require them.

Chuck Library with Existing Centering Bells

C Series allows the operator to enter information for centering bells when setting up a job. These chucks can be saved in the tool library for any future jobs that would require them.

Graphic Representation of Lens

After entering the parameters of the lens, a graphic representation of the lens will appear in the viewport on the screen. This allows the operator to verify that the correct parameters were entered. If there is no part showing in the viewport, the parameters that were entered define a geometrically impossible shape.

Tool Path Preview Animation

The animation preview will show a 3D model of the complete tool path. It can be used to verify that each process is set up correctly and will run as expected. If a collision is detected, the crashed portion of the center spindle will turn red.

C Series Optical Centering Software is available on the PRO 160C optical centering machine.