SPIE Optifab

See the latest optical manufacturing technology that gives your company a competitive edge

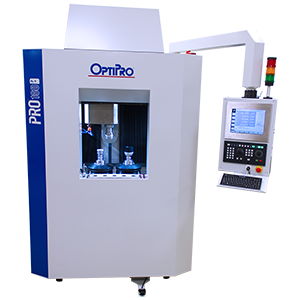

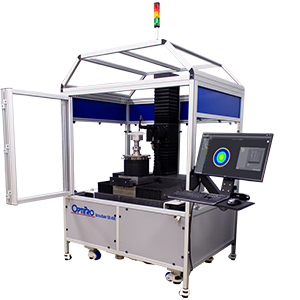

OptiPro will be exhibiting in booth 821 at SPIE Optifab (October 17 – 19, 2023 at the Rochester Riverside Convention Center in Rochester, NY). Experience the latest technology that is reshaping the precision optics industry. Our 30′ x 30′ exhibit space will showcase 7 different manufacturing and metrology solutions engineered to help companies become more productive than ever before. See live demonstrations that focus on grinding, polishing, and measuring a wide range of optical components, from spherical and aspheric lenses to freeform optics.

900

Sq. Ft. of Booth Space

7

Machines and Metrology Solutions

3

Technical Presentations

2

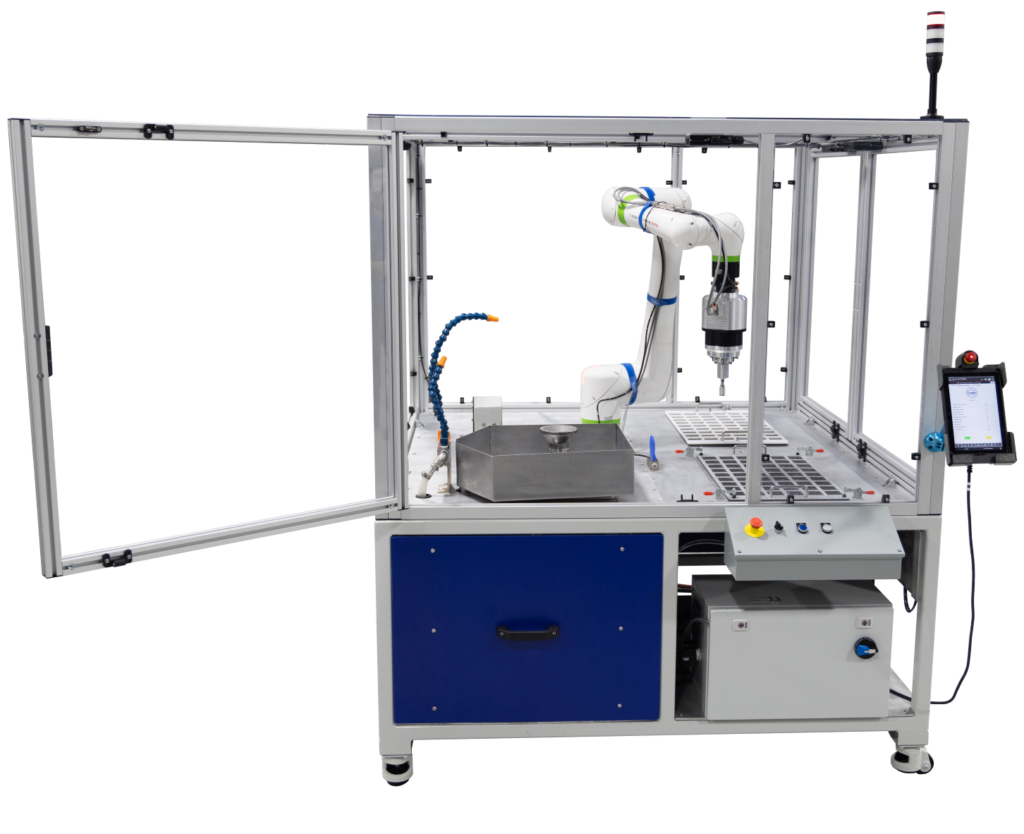

Automation Solutions

Multisensor Measurements on the ZEISS O-Inspect 322

Technical Presentations: Monday, October 16th and Wednesday, October 18th

Title: Manufacturing Process Flow for Freeform Optics

Presenter/Author: Franciscus L. Wolfs, OptiPro Systems, LLC

16 October 2023 • 8:20 AM – 8:40 AM EDT

Abstract: Freeform optics are becoming increasingly prevalent in optical systems as designers realize their numerous benefits. With these new benefits come manufacturing challenges that require adaptation of existing best practices while also developing new techniques. Geometries are becoming more complex, surface tolerances are tightening, and desired production times are decreasing. To successfully manufacture freeforms, it is important to lower the overall operating cost. To do this, there should be a focus on simplifying each operation. This presentation explores new techniques and best practices developed by OptiPro including fixture design, on-machine probing, and process optimization, and advanced freeform manufacturing software.

Title: Ultrasonic Machining of Optical and Ceramic Materials

Presenter/Author: Michael J. Cahill, OptiPro Systems, LLC

16 October 2023 • 9:20 AM – 9:40 AM EDT

Abstract: Hard glass and ceramic materials can present substantial challenges in the manufacturing process due to their tough mechanical properties. To minimize the amount of sub surface damage (SSD), slow processing speeds and tool wear are common when dealing with these materials. To combat this OptiPro has developed an ultrasonic grinding technology called OptiSonic, which, through testing, has shown a reduction of SSD, leading to reduced processing times and minimized tool wear. This paper will show the benefits of using ultrasonic machining on these materials.

Title: Automation in Optical Manufacturing: Beveling and Part Handling

Presenter/Author: Mitchell J. Sedore, OptiPro Systems, LLC

18 October 2023 • 8:00 AM – 8:20 AM EDT

Abstract: With labor shortages and difficulty in getting experienced technicians, automation can increase production and efficiency with less labor required. A robot can perform the repetitive tasks that can lead to worker burnout and free technicians up to perform more demanding tasks. Additionally, automation can reduce time between parts and run lights out, leading to increased machine time up, part quantity generated, and profitability. This presentation will showcase OptiPro’s Revel, a robotic beveling system as well as other off the shelf and custom automation solutions.

If you have a challenge that you would like solved, or just want to enhance your optical manufacturing and metrology processes, we encourage you to set up a one-on-one meeting in OptiPro's in-booth conference room.