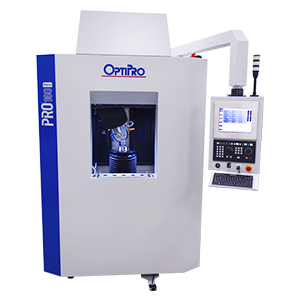

PRO 160 UFF Aspheric Lens Polishing Machine: 10-160 MM Optics

-

Overview

PRO 160 UFF Overview

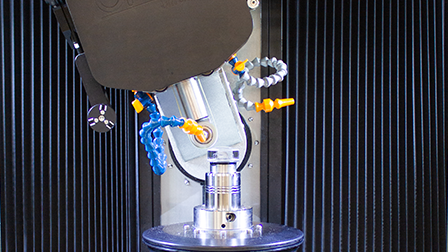

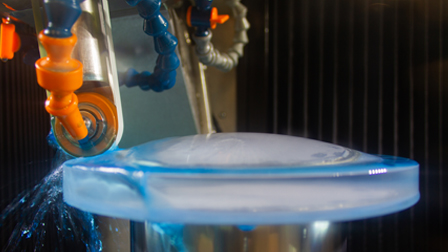

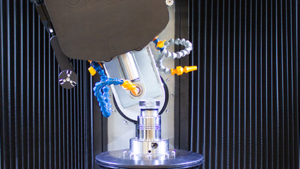

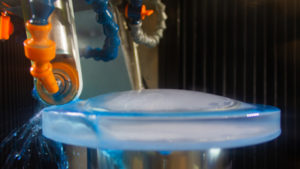

The PRO 160 UFF aspheric lens polisher is capable of rapid prototyping to high volume production of precision aspheres up to 160mm in diameter. PRO 160 UFF streamlines the asphere production process by making it possible to polish ground surfaces with high removal rates (pre-polishing not necessary). This platform utilizes UltraForm® Finishing (UFF™), which involves a moving belt of polishing material wrapped around a precision compressive wheel delivering 1/2 wave p-v or better accuracies. The PRO 160 UFF can be equipped with a variety of polishing belts ranging from classic polyurethane to uniquely formulated materials depending on the application. The flexibility of UFF allows for all types of aspheres to be polished, including those made from optical glasses, advanced ceramics, crystals, and metals.

High quality machine components and innovative software on the PRO 160 UFF help companies achieve faster cycle times and throughput of precision aspheric lenses:

- Better finishing: Stiff granite machine base to provide vibration dampening

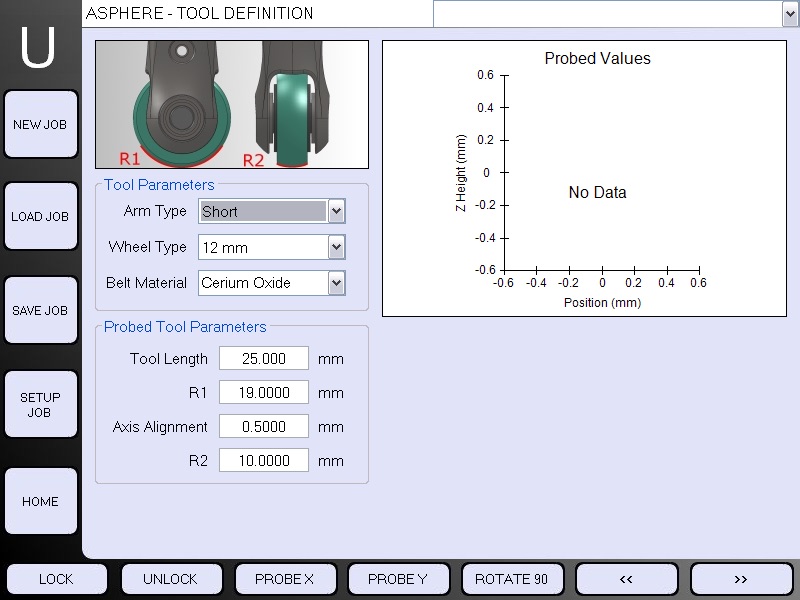

- Faster set-ups: Easy-to-learn U Series software guides operator through process (automatic tool path optimization)

- Process consistency and durability: Moving belt of polishing material provides 1,250mm of linear tool surface

- Process flexibility: Variety of precision belts utilizing classic polyurethane to uniquely formulated materials ranging from 1/2 to 250 micron abrasive for grind to final polish

- Faster cycle times: Quickly polish directly after grind with high removal rates

- Extensive material processing: Variety of fixed and loose abrasives can be utilized to polish optical glasses, crystals, ceramics, and metals such as stainless steel lens mold inserts

- Difficult geometries made easy: Multiple wheel options for finishing down to 5mm concave aspheres

- Deterministic corrections: On board removal function measurements and feedback from metrology instruments for correcting rotationally symmetric or asymmetric parts

- Safer touch-offs: Non-contact probing won’t scratch polished part

- Small footprint: Self-contained with all peripheral items within machine

- Mobility: On wheels for easy movement, leveling feet for fast set up

- Easy to service: Maintenance items readily accessible

The impressive capability and versatility of the PRO 160 UFF allows your company to achieve high precision polishing of aspheres with unprecedented efficiency.

-

Specs

PRO 160 UFF Technical Specifications

UltraForm Finishing Machine Specifications* PRO 80 UFF PRO 160 UFF UFF 300 UFF 500 Workpiece Optimal Diameter Range 10-80 mm (.39-3.14") 10-160 mm (.39-6.3") 10-300 mm (.39-11.8") 25-500 mm (.98-19.7") Maximum Plano Diameter** 100 mm (3.9") 200 mm (7.87") 300 mm (11.8") 500 mm (19.7") Maximum Weight 15 kg (33 lbs.) 25 kg (55 lbs.) 23 kg (51 lbs.) 170 kg (374.8 lbs.) Work Spindle** Spindle Speed 0-1,500 RPM 0-600 RPM 0-500 RPM 0-200 RPM Hydro-Expansion Standard Standard Standard Standard Vacuum Chuck Standard Standard Standard Standard C-Axis Position and Hold Standard Standard Standard Standard Travels X-Axis Travel 250 mm (9.8") 420 mm (16.5") 500 mm (19.7") 1,200 mm (47.2") Y-Axis Travel 6 mm (0.24") 6 mm (0.24") 400 mm (15.7") 700 mm (27.6") Z-Axis Travel 140 mm (5.5") 220 mm (8.7") 500 mm (19.7") 500 mm (19.7") B-Axis Travel -60° to 60° -60° to 60° -90° to 90º -90° to 90° C-Axis Travel 0 ° to 360° 0 ° to 360° 0 ° to 360° 0 ° to 360° Communication Interface Ethernet Standard Standard Standard Standard USB Standard Standard Standard Standard Machine Dimensions Width 1,000 mm (39") 1,400 mm (55") 2,110 mm (83") 2,570 mm (101") Depth 1,500 mm (59") 1,730 mm (68") 2,515 mm (99") 3,700 mm (146") Height 2,440 mm (96") 2,440 mm (96") 2,700 mm (106") 3,020 mm (119") Weight 1,600 kg (3,500 lbs.) 1,950 kg (4,300 lbs.) 3,400 kg (7,500 lbs.) 5,750 kg (12,650 lbs.) Workpiece Probing Standard Standard Standard Standard Tool Probing Standard Standard Standard Standard Asphere Fabrication Standard Standard Standard Standard Non-Rotationally Symmetric Correction Optional Optional Optional Optional Freeform Fabrication N/A N/A Optional Optional * Specifications subject to change. Contact OptiPro for the latest specifications.

** Machine is capable of manufacturing maximum plano size in small volume. For medium and large production quantities of max plano size, consider OptiPro’s larger platform. -

Video