Hyundai Wia Machine Tools

Known as South Korea’s largest machine tool builder as well as the leader, Hyundai Wia Machine strives for continuous improvement for their machines. Hyundai Wia Vertical Machining Centers boast durability and rapid feed rate which compliments a high production environment. Hyundai Wia Horizontal Machining Centers feature T-type all-in-one rigid bed design and built-in gear type chilled spindle that delivers power and long-term rigidity; built to cut through the toughest material and customizable up to 120 tools. Hyundia Wia CNC Turning Centers are created for multi-tasking operation with heavy duty box guideways.

Hyundai Wia CNC Turning Centers

Hyundai Wia Vertical Machining Centers

Hyundai Wia Horizontal Machining Centers

Introducing the New Hyundai Wia Product Line Up

-

HS6300/8000II

Horizontal Machining Center HS6300/8000 II, designed by Hyundai WIA with years of expertise and the latest technology, provides high speed, high performance and maximum productivity.

Next Generation High Efficiency Machining Center

- High Rigidity Box-type Structure

- A symmetrical structure design with the center of gravity of Z-axis and transfer axis matching

- Easy chip disposal with direct chip discharging structure

- Best-in-class rapid traverse rate of 60m/min (2,362ipm)

- Machining of the largest workpiece in its class

- ATC design capable of attaching the largest tools in its class

-

HS5000II

Horizontal Machining Center HS5000 II, designed by Hyundai WIA with years of expertise and the latest technology, provides high speed, high performance and maximum productivity.

State-of-the-Art Mechanism Design, High-Precision Structure

- 15,000rpm high-performance built-in spindle

- X/Y/Z axis rapid traverse rate : 60m/min

- Ball screw shaft cooling system applied

- High rigidity 3-point support bed structure

- Large dia. Ø50 mm (2″) ball screw applied

- Ring type magazine standard application

- 60T magazine Max call time : 2.9 sec

- Best-in-class tool change time (c-c) : 2.6 sec

-

SE2200

The CNC Turning Center SE Series, designed with HYUNDAI WIA’s engineering expertise to maximize productivity by enhancing rigidity and accuracy of machining.

Excellent Machining Performance, Y-axis CNC Turning Center

- 30° slanted one-piece bed structure with high rigidity

- Compact product size allows installation in small areas

- Improved user convenience by applying the latest controller of FANUC

- Ensured high-rigidity applying Roller guideway on all axes (X/Z-axis: 30/36m/min)

- Prepared user-oriented lineup including long-bed, mill turret and sub-spindle

- Integrated processing through synchronized control of Main/Sub spindle

- Ergonomic design for convenient access to chuck and tool

- Stabilized unit structure to minimize thermal displacement

-

KF3500/5A

KF3500/5A developed with application of accumulative know-how and new technology of Hyundai Wia is a next-generation machining center featuring optimal performance in complex form machining.

Best Performance in the Class & Vertical Machining Center for 5-axis Machining

- A/C axis high rigidity roller gear cam drive method applied

- Vastly superior in power delivery efficiency and strength compared to worm gear of other companies

- Rapid traverse rate of A axis 30rpm and C axis 40rpm

- High-speed 12,000rpm spindle (Opt. 15,000/20,000rpm)

- High-speed tool change time (C-C) 3.4 sec

- High-speed roller type LM guide in all axes

- Convenient work loading through crane with top cover featuring open structure

- Compact design suitable for installation in restricted space (6.5㎡)

- Applying the latest controller of FANUC 0i PLUS

-

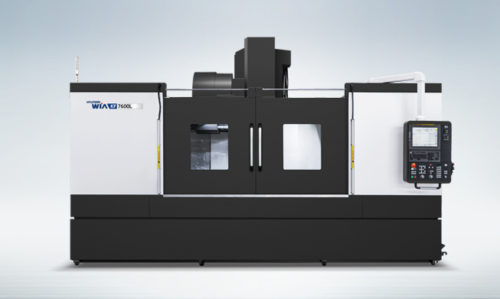

KF7600L

KF7600L, developed by applying the accumulated know-how and the latest technology of Hyundai WIA, is a next-generation machine tool optimized for processing products with long material lengths through the application of a large and wide table.

Vertical Machining Center with Best-in-class Performance & Wide Machining Area

- Large table application for machining long parts

- Wide structure of 2,100mm (82.7″) X-axis

- High rigidity with Y-axis 4way design

- Rapid traverse rate (X/Y/Z) : 30/30/24 m/min

- High speed/High rigidity LM guide in all axes

- Securing rigidity by applying 3-row ball screw support bearings

- 2 way interior screw chip conveyor (Std.)

- Bed flushing coolant, Upper-type chip conveyor standard application

-

KF-II Series

The KF-II Series is a vertical machining center that is a great improvement on the existing KF series, Hyundai Wia’s steady seller. By providing high-precision machining through quality improvement of the spindle and customized machining through various spindle line-ups, this product will contribute to maximizing customer productivity.

Most Versatile Vertical Machining Center

- High-precision machining by improving spindle quality

- Improved user convenience by applying the latest controller of FANUC

- Innovative improvement in chip disposal capability by applying the upper type conveyor and bed-flushing device

- Various motors and columns provided for customized machining

- High-speed roller type LM guide in all axes