SPIE Optifab

See the latest optical manufacturing technology that gives your company a competitive edge

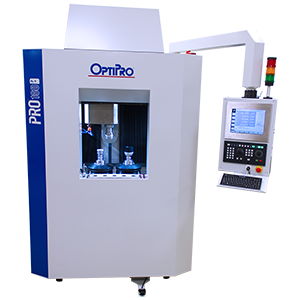

OptiPro will be exhibiting in booth 724 at SPIE Optifab (October 21 – 23, 2025 at the Rochester Riverside Convention Center in Rochester, NY). Experience the latest technology that is reshaping the precision optics industry. Our 30′ x 30′ exhibit space will showcase 6 different manufacturing and metrology solutions engineered to help companies become more productive than ever before. See live demonstrations that focus on grinding, polishing, and measuring a wide range of optical components.

900

Sq. Ft. of Booth Space

6

Machines and Metrology Solutions

3

Technical Presentations

2

Automation Solutions

Technical Presentations: October 20th, 21st, and 22nd

Title: Automation in optical manufacturing; handling, processing, and inspection

Author: Mitchell J. Sedore, OptiPro Systems, LLC

20 October 2025 • 9:40 AM – 10:00 AM EDT

Abstract: With ongoing labor shortages and fewer experienced technicians, automation offers a practical solution to boost production and efficiency with less labor. Robots handle repetitive tasks that can lead to fatigue, freeing technicians for more complex work. Automation also reduces time between parts and enables lights-out manufacturing, increasing machine uptime, output, and profitability. This presentation highlights OptiPro’s off-the-shelf and custom automation solutions for optics fabrication, focusing on advancements in part handling and in-process measurement. These systems improve consistency, reduce cycle times, and support the high precision and productivity demands of modern optical manufacturing.

Title: Sub-surface mechanical damage of fused silica glass during grinding by various sub-aperture tools with and without ultrasonics

Author(s): Tayyab I. Suratwala, Gary Tham, Rusty Steele, Lawrence Livermore National Lab (United States); James Ross, OptiPro Systems (United States); Oscar Herrera, Lawrence Livermore National Lab (United States); Mike Cahill, Mike Bechtold, Danielle Bechtold, Rob Bechtold, OptiPro Systems (United States); Frank Ravizza, Lawrence Livermore National Lab (United States)

21 October 2025 • 5:30 PM – 5:50 PM EDT

Abstract: The sub-surface mechanical damage (SSD) depth after grinding fused silica glass with a comprehensive set of sub-aperture fixed abrasive grinding tools (cup, wheel, belt, pad, rotary face mill (with and without ultrasonics)) and process parameters have been statistically measured (using the MRF wedge technique) and evaluated. Some key findings include: 1) quantitative correlations between abrasive size and SSD depth using sub-aperture tools; 2) development of novel tools providing very low SSD (<5 um) while also providing mid-spatial ripple removal, relatively high removal rate, and minimal surface figure degradation; and 3) 20% SSD depth reduction using ultrasonic tools whose mechanism is described. U.S. Department of Energy by Lawrence Livermore National Laboratory under Contract DE-AC52-07NA27344 under the LDRD program and SPP contract L23177

Title: Elastic emission machining of ultra-precision surfaces

Author: Michael Rinkus, OptiPro Systems, LLC

22 October 2025 • 4:00 PM – 4:20 PM EDT

Abstract: Elastic Emission Machining (EEM), a deterministic chemical removal process, has been shown to be one of the most effective methodologies for yielding ultra-smooth and ultra-precise optical surfaces. OptiPro has developed a process utilizing this technology in conjunction with the Department of Energy (DOE) and the National Aeronautics and Space Administration (NASA) for the polishing of ultra-precision optical substrates. By determining the proper chemical pairing of polishing slurry mixture and material substrate, OptiPro has been able to deterministically correct and smooth surfaces to <0.15 nm root mean square (RMS) microroughness, <5nm RMS mid-spatial frequency error, and < 50nm Peak-to-Valley (PV) surface error. This process is also shown to mitigate support structure print through on light-weighted optics and yields surfaces without subsurface damage.

If you have a challenge that you would like solved, or just want to enhance your optical manufacturing and metrology processes, we encourage you to set up a one-on-one meeting in OptiPro's in-booth conference room. We also will have shuttle service available at the convention center for those interested in visiting OptiPro's facility!