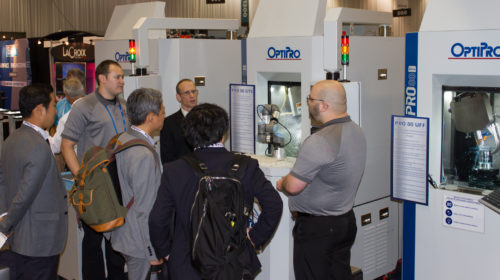

SPIE Optifab is quickly approaching! If you are planning to attend the event (October 15-17, 2019 at the Rochester Riverside Convention Center in Rochester, NY), be sure to visit OptiPro at booth 820. Our 40′ x 40′ booth will be showcasing the latest technological advancements for machining and measuring precision optics and advanced ceramic components. In this preview, we will highlight demos of a variety of metrology solutions for measuring optical components with speed, precision, and confidence. From spherical optics to complex freeforms, you will find the perfect solution for your application:

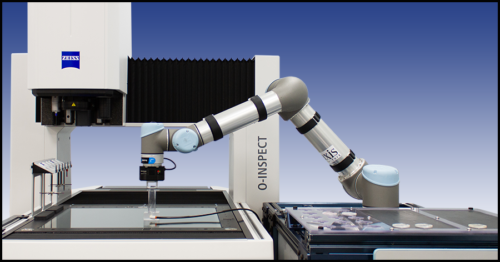

Automated Part Inspection on the ZEISS O-Inspect 543

OptiPro will be demonstrating automated measurement of lenses on the ZEISS O-Inspect 543 multisensor CMM. This solution consists of a Universal Robot UR5 collaborative robot (cobot) equipped with a New Scale Robotics NSR-PG gripper/caliper. See the NSR-PG gripper pick up a lens from the tray, measure the width of the lens while holding it, then place the lens onto a vacuum fixture on the O-Inspect 543. The O-Inspect then performs contact (probing) and non-contact (optical) measurements on the lens to determine whether the lens is in-tolerance or out of tolerance. The cobot then picks up the lens and places it in the appropriate tray for good or bad parts. Learn how incorporating automation into your metrology process can supplement your workforce, shorten turn-around times and allow your company to take on more work.

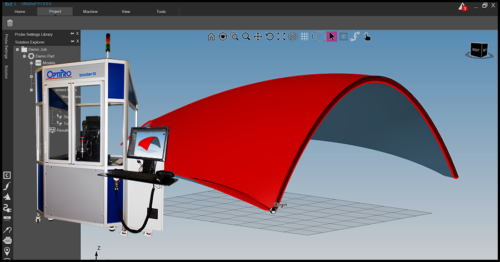

Measuring Made Easy for Complex Freeforms

See how the UltraSurf 5X non-contact metrology system, driven by our new Freeform Software, makes it fast and easy to measure freeforms and other complex optics. Several key features in Freeform Software will be highlighted, including:

- User friendly job setups: User has several options for defining their optic, including the ability to import several formats (CAD, Point Cloud, Symmetric Sag Table, Cylinder Sag Table)

- Efficient measurements:

- Can measure optical surfaces and associated datums

- A user can define multiple measurement patterns and resolutions for a specific feature (Raster, Spiral, Profile)

- On-machine alignment using the non-contact probe

- Multiple alignments can be defined without need to re-setup measurement path

- Probe Settings Library

- Software remembers optical probe settings for each measurement

- Different optical probe settings can be applied per measurement, allowing the system to automatically handle polished versus ground surfaces on the same part

- Customized Data Analysis:

- Full control of analysis process (Filtering, Fitting, Masking/Point Removal, Thresholding, Interpolation, Zernike Removal)

- Export in multiple formats (DAT, XYZ, OPM, MOD, CSV)

- PDF reporting of data

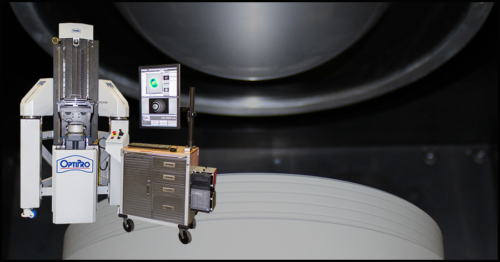

Accurate and Stress-free Spherical Measurements

See the PRO Tower measure meniscus lenses after being polished on the PRO 160P and realize the benefits of shop floor vertical interferometry. This demonstration will show how the PRO Tower Vertical Interferometer can perform high speed production metrology by quickly measuring power and irregularity of 112mm meniscus lenses. Some of the benefits that will be highlighted include:

- Flexible and easy-to-use part nesting system

- Built in scales for measuring part radius with accuracy of <0.001mm

- Easy-to-use MetroPro X software from Zygo

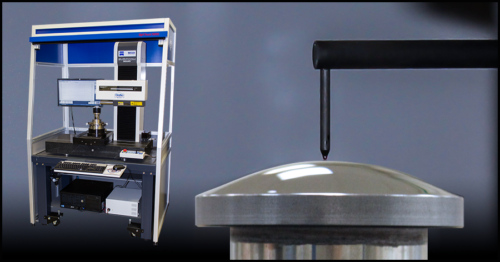

2D and 3D Measurements of Precision Aspheres

See the OptiTrace 5000 surface profilometer perform 2D and 3D measurements of precision silicon aspheres after being polished on the PRO 80 UFF. This demonstration will show the capability of the OptiTrace 5000 to perform accurate measurements with a single trace across the surface of the silicon asphere (2D measurement) or by taking multiple traces across the surface by rotating the asphere at specific intervals (3D measurement). Benefits that will be highlighted in this demo include:

- 2D or 3D data collection with Y-Theta stage

- Automatic X and Y crowning makes for easy setup

- Easy data collection and manipulation on custom made OptiTrace software

- Creation of 3D metrology files in .xyz or .dat format with OptiTrace software

Meet with the OptiPro Team

Set up a one-on-one meeting with OptiPro to discuss the perfect solution to increase manufacturing efficiency.