Picking the proper styli for your probe translates to increased efficiency & accuracy. Below are a few factors to consider when choosing a stylus.

Know your application.

The first question to ask yourself is what kind of work piece is being measured. What are you measuring? How accurate do the measurements need to be? Are there features that require depth measurement? How deep are you going into the feature? These questions will provide more direction as to what styli will work best.

Understand your environment.

Where you are taking measurements will impact what styli you use. Are you taking measurements off the shop room floor or are you taking them in a climate-controlled room? If you are taking them off the shop floor, keep in mind that the temperature of your station will vary between early morning and late afternoon.

Choosing the right sphere and stem.

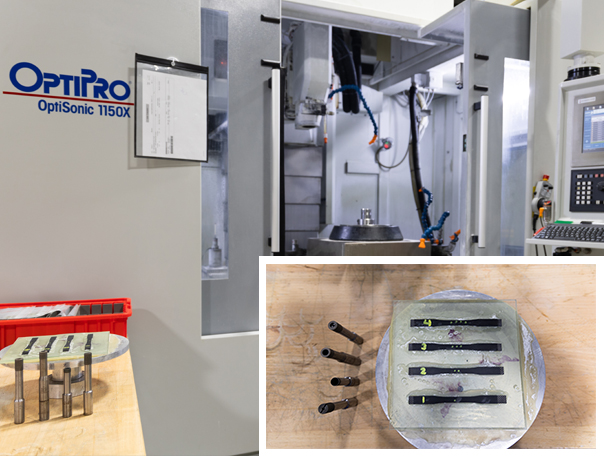

The stylus is composed of the stem and the ball. Generally speaking, the best combination is a short stem and a large sphere.

While a short stem is best, your application may have deep features that a short stem cannot reach. The default choice leans towards a short stem since the shorter the styli, the less deflection and the higher the accuracy of measurement.

In addition to choosing the right length for the stem, you will also need to consider the grade of the sphere in addition to several other factors. The grade of the ball determines how round it is. The lower the grade implies a rounder ball as well as a hefty price tag. If your shop is working on applications with tolerances larger than a few microns in error, a 10 or higher-grade sphere can work for you.

Picking the right material.

In addition to picking the right length and right grade, there is also the material to consider for the stylus. Ceramic, stainless steel, tungsten carbide, aluminum, carbon fiber are just to name a few of the stem options; the list will leave you with a lot to consider. When choosing material, make sure your stem is rigid, yet light weight. When the stem is susceptible to bending, it will distort your measurement readings. Some will argue the benefits of ceramic because metal can bend if it crashes versus ceramic shattering upon contact.

Material is also important to the sphere. You can run into the issue of it wearing away from the material it is meeting which would suggest using zirconia instead or silicon nitride if the sphere is picking up too much material on contact.

Our team at OptiPro is here to assist if you have any questions or are not sure what would be the best solution for your current set up. Contact us here.