PRO 160C Precision Optics Centering Machine: 5-200 MM Optics

-

Overview

PRO 160C Overview

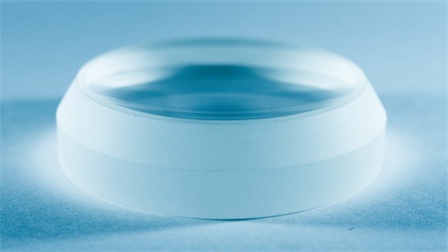

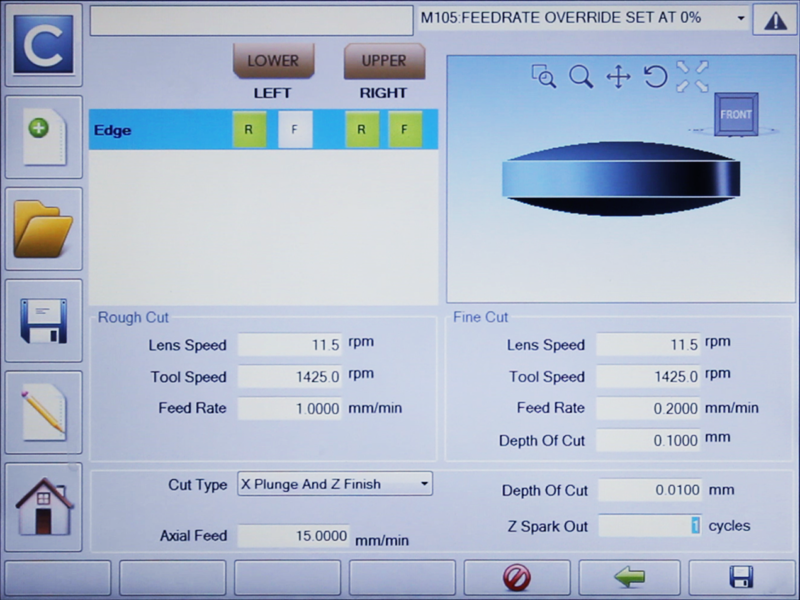

The PRO 160C CNC precision optics centering machine is capable of high precision centering of spheres and aspheres up to 200 mm in diameter. Non-circular lens shapes (truncations), facets, steps, bevels, tapers and freeform edge shaping can also be performed on the PRO 160C. For parts that have multiple geometric features, more than one operation can be completed in a single cycle, freeing the operator to run several machines at once.

Multiple advanced features help companies achieve exceptional centering production, precision, and repeatability:

- Highest quality machine components are integrated into the PRO 160C, including quick-change high speed HSK63F tool spindles that minimize setup time.

- At the core of the machine is a rigid granite base for excellent stability, ensuring highest quality and consistent part-to-part accuracy.

- Centering bells are precisely manufactured with state-of-the-art metalworking equipment in-house by OptiPro’s team of machinists. High quality centering bells minimize any damage risk to the surface of the clamped optic.

- Three options to center the workpiece – laser alignment via transmission or reflection, centering with dial indicator, or self centering.

- Proficient bell clamping technology minimizes setup time by automatically applying the desired amount of clamping force that is specified.

- Intuitive Edge Detection feature allows the operator to quickly apply necessary bevels to the optic.

- Center thickness compensation ensures accurate bevels and sag flats.

The PRO 160C CNC centering machine delivers efficient and precise processing of optical glasses, ceramics, and IR materials in a variety of shapes and sizes.

-

Specs

PRO 160C Technical Specifications

CNC Optical Centering Machine Specs* PRO 160C Workpiece Optimal Diameter Range Up to 200 mm (7.87") Maximum Workpiece Height Up 70 mm (2.76") Work Spindle Spindle Speed 0-200 rpm Work Spindle Spindle Speed 0-250 rpm Hydro Expansion Chuck 25 mm - Standard and Custom Bells Available C-Axis Position and Hold Standard Precise Clamping Pressure Up to 1,000N Tool Spindle Tool Holder Style Quick Change HSK63F Maximum Tool Diameter 220 mm (8.66") Maximum Tool Weight 6 kg (13.2 lbs.) Tool Spindle Speed 1,000 - 12,000 rpm Tool Holder Style ER40 Collet Spindle Power 7kW (9.5hp) Travels X1 - Axis Travel 95 mm (3.74") X2 - Axis Travel 95 mm (3.74") Z1 - Axis Travel 180 mm (7.08") Z2 - Axis Travel 180 mm (7.08") Z3 - Axis Travel 85 mm (3.35") C1 - Axis Travel 360° Continuous C2 - Axis Travel 360° Continuous Communication Interface Ethernet Standard USB Standard Machine Dimensions Width 1,278 mm (50.3") Depth 2,032 mm (80") Height 2,282 mm (89.8") Weight 2,494 kg (5,500 lbs.) Facility Requirements Electrical 480V Wye +/- 10%, 58A Air Supply 100PSI, 5 CFM clean dry air Laser Alignment with Transmission Optional Laser Alignment with Reflection Optional Center Thickness Compensation Standard Truncation Grinding Optional * Specifications subject to change. Contact OptiPro for the latest specifications.

-

Video