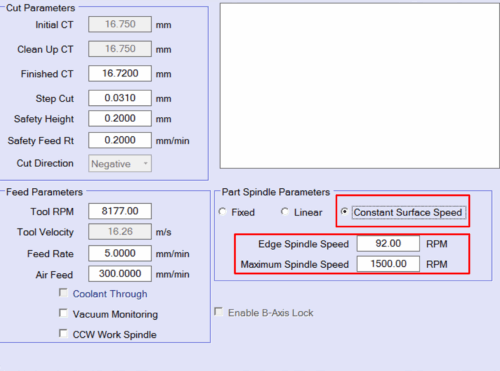

Software screen showing different part spindle parameters, with Constant Surface Speed highlighted.

Improve surface quality when grinding aspheres with Constant Surface Speed (CSS). G Series, the powerful and easy to use software that drives OptiPro’s CNC optical grinding machines, now features a CSS option for grinding aspheres. With CSS, machine operators now have three versatile contour grinding operations to choose from for grinding precision optical surfaces:

- Fixed: The work spindle speed stays constant throughout the entire cycle.

- Linear: The work spindle will ramp up/down from edge to center at a linear rate. A user will define the work spindle RPM based on its speed at the edge of the workpiece and center of the workpiece.

- Constant Surface Speed: The work spindle will automatically adjust its RPM from edge to center, while taking into account (compensating for) the changes in workpiece diameter.

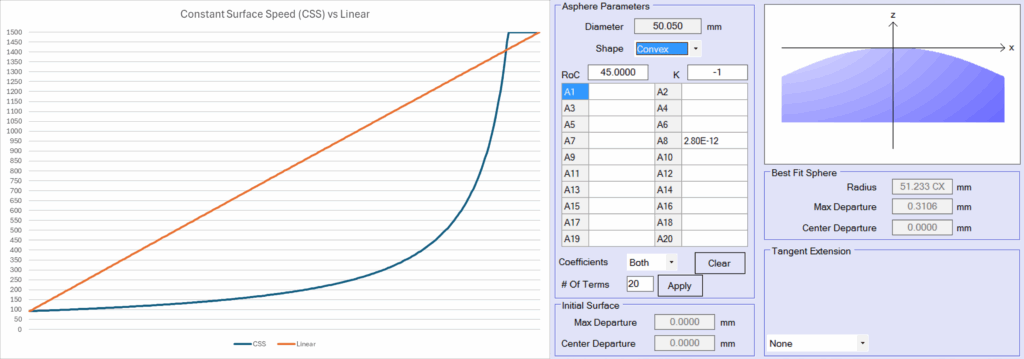

Deciding which option to choose is greatly influenced by the type of asphere you need to produce. For very mild aspheric surfaces that don’t have a lot of departure, Fixed and Linear can produce similar results as CSS in terms of surface quality. However, when grinding aspheres that have a lot of departure, CSS really shines. Because CSS promotes consistent cutting conditions while the grinding tool traverses from edge to center, technicians can expect much better surface quality compared to utilizing Fixed or Linear speeds.

Graph showing both Linear Speed and Constant Surface Speed workpiece RPM changes across the convex asphere, as defined in the asphere parameters screen.

In addition, CSS assists with producing extreme shape departures, which decreases setup time. Setup time is reduced as a result of the corrections and surface quality being dialed in quicker. With just a single RPM, as it was configured before, the operator would need to find a “sweet spot” of spindle RPM’s for extreme shapes/departures. Since CSS programs the machine to vary the RPM’s, fewer corrections are needed to achieve desired surface quality.

Ultimately, reduced setup time and better surface quality after grinding means you can get your asphere job in the hands of the customer faster. OptiPro has several grinding machines available in different platform sizes to accommodate aspheres ranging from Ø5-500mm. Contact us today to find the perfect solution for your requirements.

Ultimately, reduced setup time and better surface quality after grinding means you can get your asphere job in the hands of the customer faster. OptiPro has several grinding machines available in different platform sizes to accommodate aspheres ranging from Ø5-500mm. Contact us today to find the perfect solution for your requirements.