PRO 160 GTS Optical Lens Generator: 10-160 mm Optics

-

Overview

PRO 160 GTS Overview

The PRO 160 GTS optical lens generator is capable of rapid prototyping to high volume production of spherical and aspheric optics up to 160mm in diameter. The PRO 160 GTS features a vibration isolated granite base for ultimate precision, thermal stability, and consistent part-to-part accuracy. This compact platform has double the part size capability as the PRO 80 GTS while having only a slightly larger footprint. Engineered and built completely in the USA with high quality machine components and user friendly G Series lens grinding software, the PRO 160 GTS delivers precision optical grinding with optimal efficiency and repeatability.

Multiple advanced features on the PRO 160 GTS help optical manufacturers achieve optimal results when grinding spheres and aspheres:

- Better grinding: Stiff granite machine base + spindle construction with high quality ceramic bearings

- Process consistency: Liquid cooled spindles

- Better process control: Direct drive spindles

- More cutting power: Integral high torque spindle motor

- High accuracy tool and work spindles: HSK 63 quick-change holders for less chatter

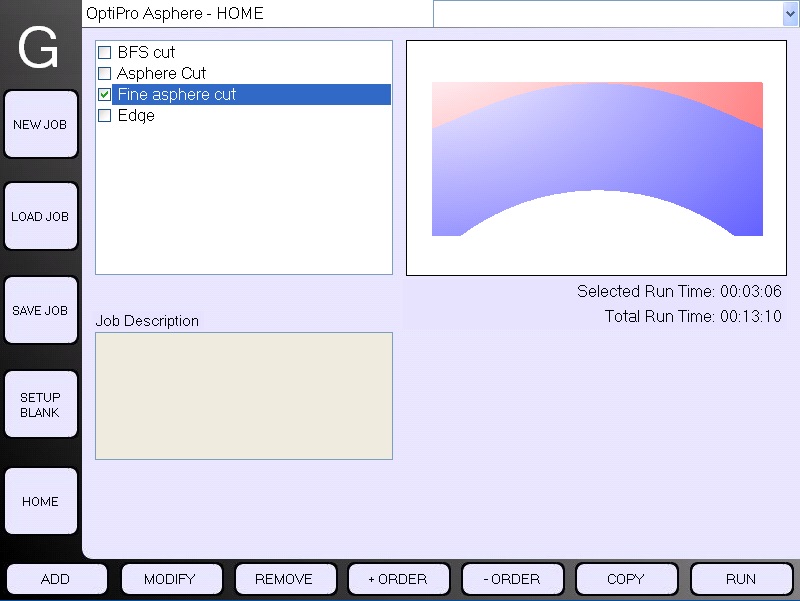

- Faster set ups: Easy-to-use GUI for precision optics with step-by-step process driven software (G Series)

- Streamlined probe interface: Easy to use, easy to customize online metrology

- Energy efficient: Servos turn off automatically

- Custom process step: Compatible with Mastercam CAM software for offline tool paths

- On board tool dressing: Safer, better dressed tool at part geometry, able to utilize tools that are otherwise unusable

- Small footprint: Self contained with all peripheral items within machine

- Mobility: Retractable wheels for easy movement, leveling feet for fast set up

Enhance your optical grinding capabilities by adding the PRO 160 GTS into your manufacturing operations.

-

Specs

PRO 160 GTS Technical Specifications

Optical Grinding Machine Specs* PRO 80 GTS PRO 160 GTS eSX 150 Workpiece Optimal Dia. Range 5-80 mm (.2-3.1") 10-160 mm (.4-6.3") 5-150 mm (.2-5.9") Max. Plano Diameter** 100 mm (3.9") 160 mm (6.3") 200 mm (7.9") Max. Weight 15 kg (33 lbs.) 30 kg (66 lbs.) 23 kg (51 lbs.) Work Spindle Spindle Speed 0-1,500 RPM 0-600 RPM 0-500 RPM Hydro Expansion Chuck Standard Standard Standard C-Axis Position and Hold Standard Standard Standard Tool Spindle Maximum Tool Diameter 75 mm (3") 160 mm (6.3") 125 mm (5") Maximum Tool Weight 4.5 kg (9.9 lbs.) 4.5 kg (9.9 lbs.) 6 kg (13.2 lbs.) Tool Spindle Speed 200-20,000 RPM 0-24,000 RPM 1,000-22,000 RPM Spindle Power (Peak) 8.7kW (11.6hp) 8.5kW (11.4hp) 14.4kW (19.3hp) Tool Holder Style HSK63F HSK63F HSK63F Coolant Thru Spindle N/A N/A Optional Twin Spindle Standard Standard Optional Travels X-Axis Travel 250 mm (9.8") 360 mm (11.8") 500 mm (19.6") Y-Axis Travel 6 mm (.24") 6 mm (.24") 400 mm (15.7") Z-Axis Travel 140 mm (5.5") 180 mm (7.1") 500 mm (19.6") B-Axis Travel -60° to 60° -60° to 60° -90° to 90° C-Axis Travel 0° to 360° 0° to 360° 0° to 360° Communication Interface Ethernet Standard Standard Standard USB Standard Standard Standard Automatic Tool Changer N/A N/A Optional Machine Dimensions Width 1,000 mm (39") 1,400 mm (55") 2,110 mm (83") Depth 1,500 mm (59") 1,730 mm (68") 2,515 mm (99") Height 2,440 mm (96") 2,440 mm (96") 2,700 mm (106") Weight 1,600 kg (3,500 lbs) 1,950 kg (4,300 lbs) 3,400 kg (7,500 lbs) Workpiece Probing Standard Standard Standard Tool Probing Standard Standard Standard Integrated Spherometer Optional Optional Optional Asphere Fabrication Optional Optional Optional Freeform Fabrication N/A N/A Optional * Specifications subject to change. Contact OptiPro for the latest specifications.

** Machine is capable of manufacturing maximum plano size in small volume. For medium and large production quantities of max plano size, consider OptiPro’s larger platform.

Machine Features

- “Rock-Solid” granite core ensures thermal stability and consistent part-to-part accuracy

- 4 controllable axes: X, Y, Z, & B with up to 4 axes of simultaneous movement

- Fagor 8065 CNC machine control with a high resolution LCD touch screen monitor

- Menu-driven data entry screens with operator prompts for process data input minimizes set-up time

- Graphical tool path verification increases safety by allowing operator to visualize the grinding operation step-by-step before actually running the part

- Quick tool change and precision tool registration with the use of industry standard tapered tool holders

- Continuous display of axes positions and distance-to-go values

- Automatic curve correction using spherometer radius measurement input

Optional Equipment

- Mist removal

- Automatic tool probe and work probe for in-process monitoring

- Coolant filtration system

-

Video