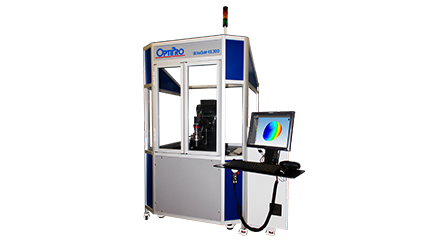

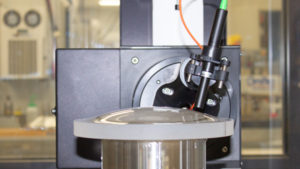

UltraSurf 4X 300 4-Axis Non-Contact Metrology System

-

Overview

UltraSurf 4X 300 Overview

Enhance your optical metrology capabilities with UltraSurf 4X 300, OptiPro’s high precision 4-axis non-contact metrology system. UltraSurf is capable of measuring various rotationally-symmetric precision optical components, including planos, spheres, and aspheres, to sub-micron accuracies. This powerful and precise instrument can perform both surface profiling and low-coherence interferometry to measure optics made from a variety of materials, including glasses, ceramics, crystals, and metals.

With UltraSurf 4X 300, you can take advantage of the following benefits:

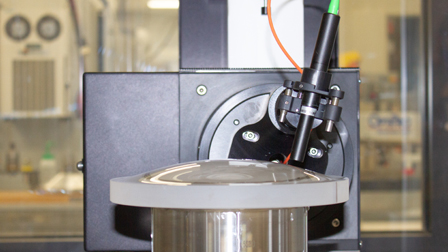

- High precision measurements: Granite base and air bearing axes allow for a stable foundation and accurate motion

- 4-axis air bearing system

- 2 linear, 2 rotary axes

- X & C axes position the part

- Z & B axes position the probe

- Highest quality air bearings and linear motor technology

- Linear: 5nm resolution

- Rotary: Sub-arc second resolution

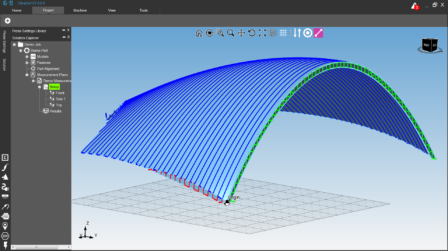

- Easy setups: UltraSurf software with intuitive graphical user interface for simple instrument operation

- Fast measurements: Aspheric measurement in under a minute

- Highly productive: Proprietary software and the use of a variety of sensors allow for multiple feature measurements in one setup

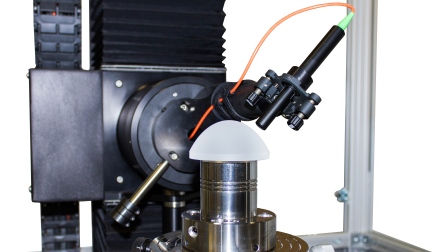

- Capable of measuring the inside and outside surfaces of hemispherical domes, depending on the probe that is utilized. One measurement with the UltraSurf can capture:

- RoC of S1 and S2

- Form of R1 and R2

- Center Thickness

- Edge Thickness Deviation (Wedge)

- Innovative software provides comprehensive 3D and 2D contour analysis and surface figure

- Perform 2D measurement or 3D measurement by creating a 3D topographical map for correction files

- Capable of measuring the inside and outside surfaces of hemispherical domes, depending on the probe that is utilized. One measurement with the UltraSurf can capture:

- Infinite asphere capability: Accurately measure ANY asphere up to 300mm in diameter

- Material flexibility: Capable of measuring a variety of materials, including optical glasses, ceramics, crystals, and metals

- Ground or polished workpieces: Multiple sensors available at different wavelengths allow for measurement of optics in the ground or polished state

- Multiple data export formats allow seamless integration with standard optical fabrication platforms.

- Non-contact metrology significantly reduces the likelihood of workpiece damage during inspection

With a small footprint to optimize floor space and exceptional ergonomics for maximum operating efficiency, UltraSurf was engineered with the customer in mind. Stay ahead of the technological curve, and your competition, with the UltraSurf non-contact metrology system.

-

Specs

UltraSurf 4X 300 Technical Specifications

Non-Contact Metrology Specs* UltraSurf 4X 300 Travels X-Axis Travel 300mm Z-Axis Travel 140mm B-Axis Travel +/- 120° C-Axis Travel 360° Continuous Resolution Linear 5.0nm Rotary 0.05 sec. Maximum Velocity Linear 20 mm/s Rotary 66 RPM Max Scanning Speed 1,000 Hz (with appropriate probe configuration) *Specifications subject to change. Contact OptiPro for the latest specifications.

-

Video