March 17, 2021 – Our Mastercam and Machine Tools Team hosted their first episode of Knowledge on Tap which showcases features from both the software and machine tool side. In Episode One, our team showcased Raster to Vector and 5-Axis Toolpath project onto curves.

Raster to Vector

Raster to Vector has been a feature in Mastercam for a long time and has evolved to taking an image and converting it to cuttable geometry. Our team discovered that it is easier to create an outline from black and white images.

Multi-Axis Project Curve

In this episode we manipulated the geometry and rolled it around the sphere. Then we created the tool in tool assembly, picked the cutting parameters, selected our wireframe then projected onto our working surface. To test out the process, we can plug it into our machine simulation. Mastercam comes with some preloaded machines, but if your model is not present, reach out to OptiPro’s Mastercam team and we will work to have your model created and uploaded for your application. Postability founder, Dave Thomson, talks about Machine Simulation in Mastercam in this video if you are interested in learning more.

This is a great feature to start out with when you are just getting into multi-axis. An easy way to think of it is like a contour tool path with five-axis capabilities built in. It’s a nice feature to use for picking out corners, getting into tight places or engraving a sphere like we have done in this episode.

TCP/RTCP

TCP or RTCP as it also referred to in the industry stands for Tool Center Point Control or Rotary Tool Center Point Control. In the Fanuc world, you may hear this referred to as G43.4 which still refers to the coordinates deriving from the tool tip. Normally coordinates are coming from home positions. The additional benefit you can see from this feature includes better tool life, better surface finishes, faster cycle times, ease of programming and reading.

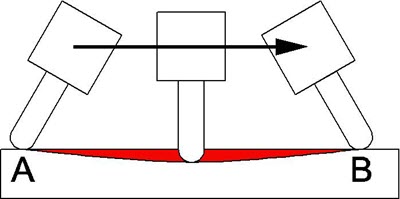

In the below image showcases an additional benefit: local tool gouging. We are able to keep the tool tip perpendicular to the surface of the object.

Tool Path Without TCP

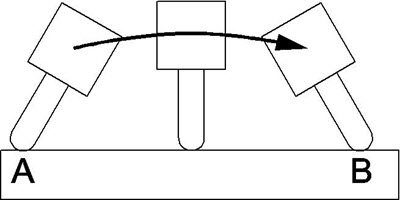

Tool Path With TCP

With the 5-Axis Package on the Robodrill, you also have Tool Axis Control which keeps the tool perpendicular to the surface through the whole tool path. This is also featured in the High-Speed Smooth TCP. The features allows for part geometry programming independent of machine kinematics and ensures the the tool tip precisely follows the part profile. Check out the video clip below to see more:

Outside of our machine tools division, OptiPro’s optics division recently wrote an article about RTCP on their 5-Axis machines and the kinematics involved. Click here to read more!

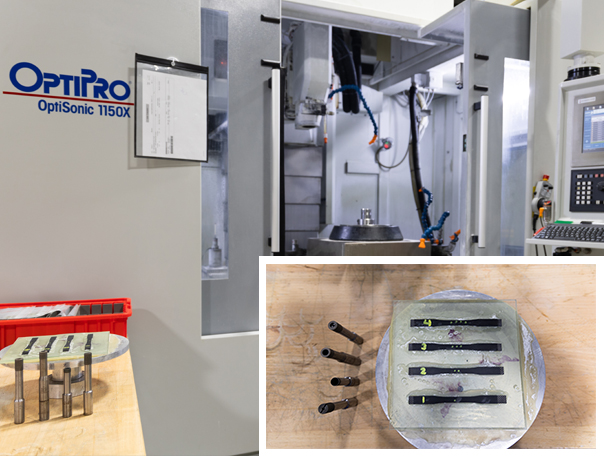

Fanuc Robodrill Showroom Model

Our first episode was featured on a Fanuc 5-Axis Robodrill which is available on our showroom floor.

Medium Bed Robodrill with 21 Tools and 10,000 RPM Spindle