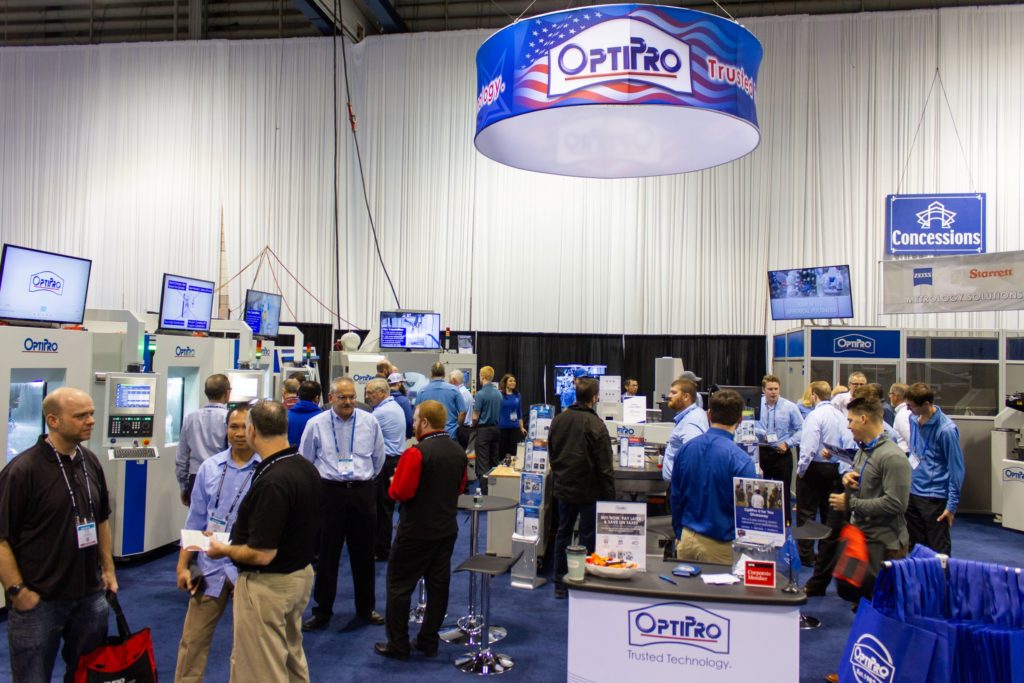

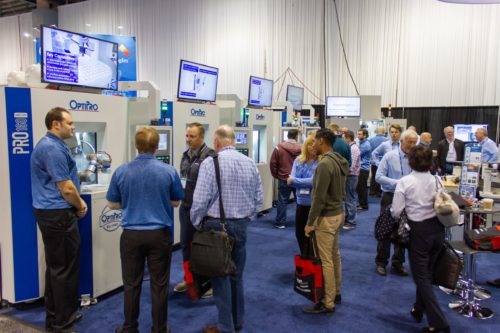

SPIE Optifab was a major success with 2,292 total registered attendees (up 21% from 2017). Visitors of OptiPro’s booth had the opportunity to see live demonstrations of a dozen different optical manufacturing and metrology solutions. The latest technological advancements were on display, including:

- Automated part-loading with a collaborative robot (cobot) on the PRO 160 GTS CNC optical grinding machine

- High speed polishing of spherical lenses with in-process tool truing on the PRO 160P+

- Silicon asphere polishing with coolant on the PRO 80 UFF CNC asphere polisher

- Fast core-drilling to produce optical blanks on the OptiSonic 550X

- High speed non-contact asphere and freeform metrology on UltraSurf

Capabilities that keep you ahead of the competition

The front of the booth featured a demonstration of cobot automation on the PRO 160 GTS. Auto-loading and unloading of 20mm lenses was performed using dual grippers and without the need of a pre-centering station, allowing companies to quickly realize the benefits of an automation solution from OptiPro.

The front of the booth featured a demonstration of cobot automation on the PRO 160 GTS. Auto-loading and unloading of 20mm lenses was performed using dual grippers and without the need of a pre-centering station, allowing companies to quickly realize the benefits of an automation solution from OptiPro.

A demo of high speed polishing of 112mm meniscus lenses on the PRO 160P+ showcased the capability of in-process tool truing. Dual lower spindles allow for uninterrupted tool truing – no need to change tools – so you can maximize production of spherical optics.

Optical manufacturers serving the aspheric optics market were able to see the capabilities of UltraForm® Finishing by watching a demo of Silicon asphere polishing on the PRO 80 UFF. By utilizing a moving belt of polishing material, the process is capable of producing optical quality surfaces on Silicon with only coolant.

Companies that provide blanks to optical manufacturers were able to see technology that can make blanks with high efficiency and precision. The OptiSonic 550X ultrasonic machining center performed ultra-fast core drilling to produce high quality optical blanks. In-sequence tool probing ensured process stability and prevented part damage.

If you missed Optifab, you can check out videos of these demonstrations here:

Watch SPIE Optifab 2019 Demos >>

Technical Presentations and an Optical Technician Course

Advancements in freeform optics manufacturing and metrology was the focus of two technical presentations, as well as an in-booth demonstration and Optical Technician Course. Frank Wolfs, Senior Algorithm Engineer, gave a technical presentation on “Advanced in freeform manufacturing” on Wednesday, October 16th. The talk focused on challenges associated with manufacturing freeform optics and OptiPro’s solutions for them, including PROSurf freeform CAM software. On Thursday the 17th, Frank Wolfs gave an in-booth demonstration on the features and capabilities of PROSurf.

Advancements in freeform optics manufacturing and metrology was the focus of two technical presentations, as well as an in-booth demonstration and Optical Technician Course. Frank Wolfs, Senior Algorithm Engineer, gave a technical presentation on “Advanced in freeform manufacturing” on Wednesday, October 16th. The talk focused on challenges associated with manufacturing freeform optics and OptiPro’s solutions for them, including PROSurf freeform CAM software. On Thursday the 17th, Frank Wolfs gave an in-booth demonstration on the features and capabilities of PROSurf.

Also on Wednesday, October 16th, Scott Defisher, Senior Research Engineer, delivered a technical talk on “Advancements in non-contact freeform metrology with datum structures” which presented practical examples of non-contact freeform metrology with the UltraSurf along with considerations of datum features. The next day, Scott Defisher taught an Optical Technician Course SC1280: Measuring Precision Freeform Optics, which provided a basic understanding of current industrial techniques for freeform metrology. This course included a lecture portion as well as a live demonstration of the UltraSurf 5X non-contact metrology system in OptiPro’s booth.

We want to thank everyone who was able to stop by OptiPro’s booth at SPIE Optifab!

Relive your visit to OptiPro’s booth by checking out photos from the event below:

View SPIE Optifab 2019 Photos >>

If you are in the market for a solution that can take your optics or ceramics manufacturing to the next level, we encourage you to reach out to us. Whether you are looking enhance production of planos, spheres, aspheres, or freeform optics, OptiPro has the perfect machine for your application.