SPIE Optifab is quickly approaching! If you are planning to attend the event (October 15-17, 2019 at the Rochester Riverside Convention Center in Rochester, NY), be sure to visit OptiPro at booth 820. Our 40′ x 40′ booth will be showcasing the latest technological advancements for machining and measuring precision optics and advanced ceramic components. In this preview, we will highlight the demos you can experience that will make your manufacturing process more efficient. From spherical optics to complex freeforms, you will find the perfect solution for your application:

Automated Part Loading and Unloading

See Automation Solutions designed to supplement your workforce, shorten turn-around times and allow your company to take on more work. OptiPro will be demoing a collaborative robot (cobot) configuration designed to accompany the PRO 80 and PRO 160 line of optical fabrication machines. Realize the benefits of automation by watching auto-loading and unloading of spherical optics after being generated in the PRO 160 GTS CNC optical grinding machine. This cobot is equipped with dual grippers, allowing the ground spherical optic to be unloaded and immediately loading an optical blank into the machine in one step, without the robot arm having to retreat to the part tray.

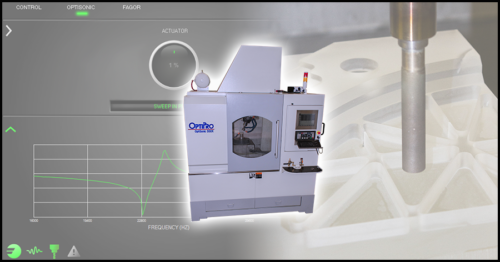

Faster Machining of Brittle Materials

See how the OptiSonic 550X ultrasonic machining center, powered by proprietary software, is able to perform rapid core drilling to produce optical blanks. This demo will highlight IntelliSonic software, which allows the OptiSonic 550X to maintain optical cutting performance through two key capabilities: adaptive ultrasonic frequency control and automated tool frequency tuning. Both features help reduce force on the tool and part during machining, allowing the operator to increase feed rates and depth of cut that can’t be matched by conventional machining. Optical blanks produced via core drilling will be auto-loaded into the PRO 160 GTS to generate spherical optics (see above).

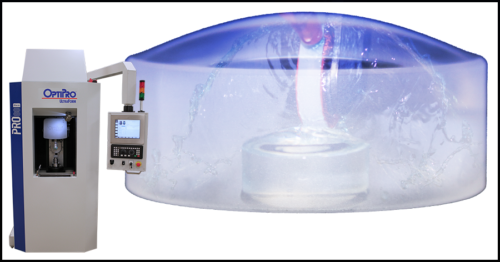

Streamlined Polishing of Aspheric Optics

See the PRO 80 UFF CNC asphere polisher quickly polish ground aspheric surfaces with high removal rates (no pre-polishing necessary!). OptiPro will be demonstrating the capability of the PRO 80 UFF by polishing silicon aspheres directly after fine grinding. Powered by U Series Deterministic Polishing Software, see how the PRO 80 UFF can polish aspheres to sub-micron specifications faster and easier than ever before.

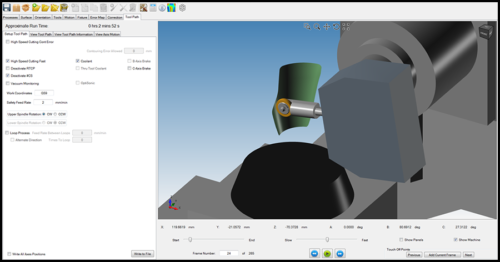

Simplifying Freeform Optics Production

See how PROSurf freeform CAM software is able to make setting up and running freeform optic jobs easy and adaptable for manufacturing. PROSurf freeform CAM software, which generates tool paths specific to OptiPro’s optical grinding and polishing machines, will be running demonstrations showing the steps involved to make various freeform parts ready for manufacturing. PROSurf demos will highlight:

- Ability to grind and polish complex rotationally-symmetric optics defined with CAD models

- Ability to grind and polish acylinders

- Ability to grind and polish freeform optics

- Benefits of using the OPM error format when making metrology-driven figure corrections

Meet with the OptiPro Team

Set up a one-on-one meeting with OptiPro to discuss the perfect solution to increase manufacturing efficiency.