PROSurf Freeform CAM Software

PROSurf is an innovative CAM package tailored specifically toward the manufacturing of freeform optical shapes, allowing companies to produce aspheric cylinders, toroids, and various freeform optics faster than ever before. PROSurf can generate tool paths specific to optical grinding, UltraForm Finishing (UFF), and UltraSmooth Finishing (USF) operations on OptiPro machines. The software supports a range of inputs to define the surface and a number of different metrology formats for corrective tool path generation.

Deterministic Freeform Generator

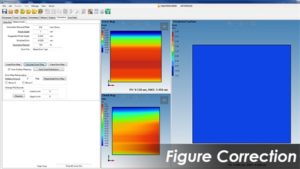

Figure Correction

Acylinder Definition

Acylinder 3D Animation

Multiple features in PROSurf make setting up and running freeform optics easy and adaptable for manufacturing:

Metrology-Driven Figure Correction

To be able to meet precision optical tolerances on freeform surfaces, it is crucial to have the ability to figure correct the surface based on metrology data. PROSurf has the ability to perform metrology-driven figure correction for both grinding and polishing processes. The software supports multiple different inputs for error maps: dat, xyz, mod, csv, and opm. The opm extension is a custom, simple-to-use OptiPro Metrology format that allows the user to have the option of inputing error map types that are not currently available from other software. This also allows for additional offline manipulation of the data knowing that it can be brought into PROSurf if it is formatted properly.

Shape Definition

PROSurf supports a number of input types to define the surface being processed. The first option is for the user to input a solid model of the surface. From the model, the user selects the surface that is desired for processing. The second option available to the user is to define the surface mathematically. This option is currently available for aspheric cylinders because of their prevalence. As other freeform shapes become more common in the industry, they will be generalized into predefined shapes in PROSurf. The final option for surface definition in PROSurf is to import a point cloud. With the point cloud, the quality of the processed surface will be directly affected by the density of the point cloud brought into PROSurf.

Point Distribution Control

Unlike traditional CAM software, the user has more control over the point distribution in PROSurf. For equation and point cloud based shapes, the user’s default option is an evenly spaced x and y grid. For a solid model, the default option is to use the built in U and V directions to follow the surface. For most surface types, there are additional options for spacing distributions.

Rapid Material Removal

Rastering is the basic motion in PROSurf to generate passes across the surface in either normal or tangent contact with the surface. To optimize process time efficiency, the rapid material removal tool path can be utilized in PROSurf. Rapid material removal allows you to efficiently go from a blank to the rough shape of the surface. With rapid material removal, the tool path that is generated will start with a flat top of the blank and rough the entire surface out in a single program. This method also detects whether the tool will be cutting air between the step over points and, if so, the lines will be skipped over in order to reduce cycle times and increase efficiency.

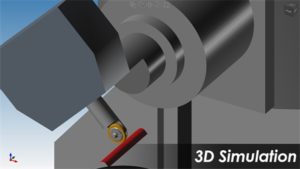

3D Tool Path Simulations

The software contains built-in models of several OptiPro machine platforms as well grinding, UFF and USF tool models to provide a 3D simulation of the generated tool path in PROSurf. The tool path simulation is essential as it detects any potential collision issues before they are run on the machine, ensuring peace of mind for the operator.

Revolutionize freeform optics manufacturing with PROSurf CAM software and OptiPro grinding and polishing solutions.