Machine Tools

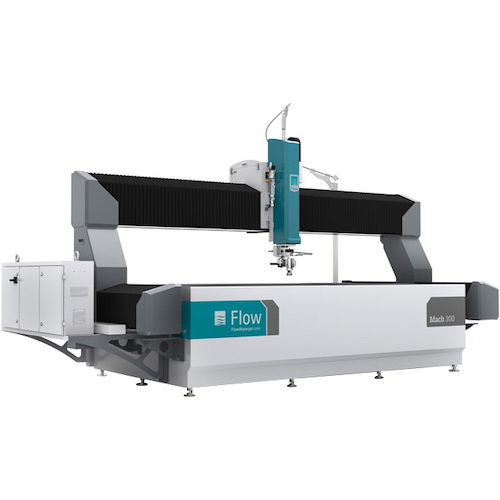

OptiPro Systems is the exclusive distributor of leading-edge precision machine tools and solutions, including: Nakamura-Tome multi-tasking turning centers, Fanuc RoboDrill machining centers and Robocut Wire EDM Machines, Hyundai Wia machine tools, KIWA horizontal machining centers, Yasda precision machines, Methods machining centers, OKK horizontal machining centers, Weiler Precision Lathes, and Swistek Swiss-type CNC lathes. We are also proud to be the NY State dealer of Flow waterjets, Awea Bridge Mills, and Dynapath Tool Room Solutions.

Conveniently located in Ontario, NY, our showroom is open to visit and see in-stock machines. Call us today for more information!

If your company is located in Buffalo, Niagara Falls, Rochester, Syracuse, Jamestown, Binghamton, Utica, Schenectady, Albany, Watertown, Potsdam, Plattsburgh, or anywhere else in upstate NY, contact OptiPro and we will help find the right machine tool for your application.