UFF 500 Large Asphere & Freeform Polishing Platform: 10-500 MM Optics

-

Overview

UFF 500 Overview

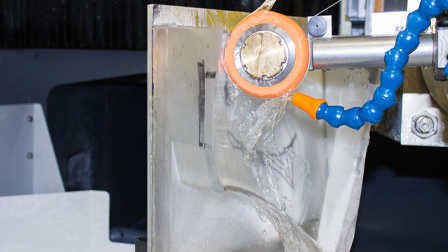

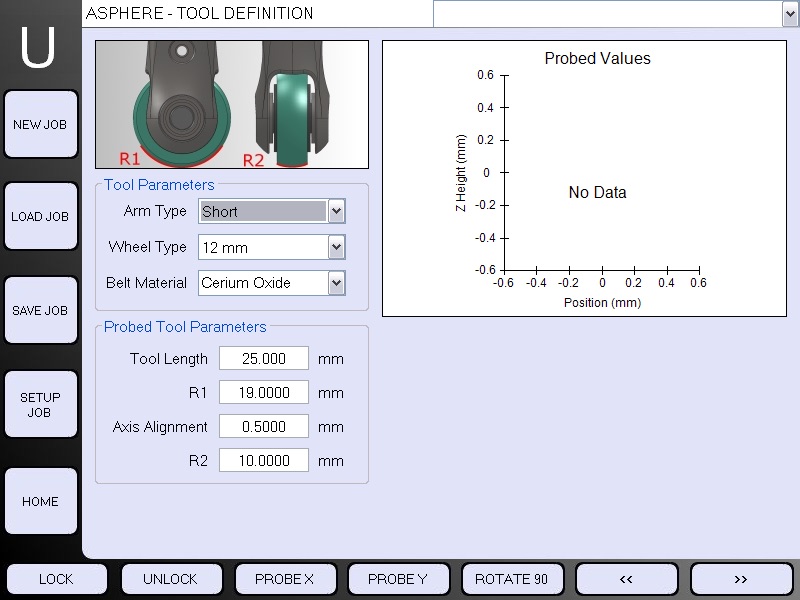

UFF 500 is a large, 5-Axis CNC sub-aperture polishing platform ideal for a variety of optics up to 500mm in diameter, including aspheres, aspheric cylinders, and freeforms. The unique axes configuration provides an accurate and versatile platform for deterministic finishing brittle materials such as glass, ceramics, and hardened steels. The straight forward user interface and probing routines provide a tool that opticians and CNC machinists alike can use to polish aspheric and freeform optical surfaces with reduced setup times. The powerful CNC control can accept freeform surface files from OptiPro’s PROSurf freeform CAM software for a full 5-axis polishing process. UFF 500 provides a robust, deterministic process essential for the finishing of quality optical surfaces in large workpieces such as windows, domes and mirrors. The machine entails 3 linear (X, Y, Z) and 2 rotary (B, C) axes. It can have X and Y travels up to 3m by 3m and custom rotary axes configurations for specific process requirements.

UltraForm® Finishing (UFF™) is OptiPro’s patented 5-axis sub-aperture polishing system that polishes ground surfaces to finished specifications using a deterministic algorithm. UFF involves a moving belt of polishing material wrapped around a precision compressive wheel delivering 1/2 wave p-v or better surface form error. OptiPro’s UFF now incorporates over 30 types of precision belts utilizing classic polyurethane to uniquely formulated materials. This variety of fixed and loose abrasive combinations makes UFF the best solution for polishing a wide variety of optical glasses and ceramics and stainless steel lens mold inserts.

Precision Finishing

- Deterministic finishing of aspheres, and freeforms

- Figure error correction using feedback from a metrology system such as the UltraSurf

Save Time

- Finish aspheres in a fraction of the time with high removal rates and precision

- Polish directly after grind…No need to pre-polish!

- On-board metrology for faster setups

Make Money

- Predictable low cost consumables

- Deterministic CNC polishing means consistent and reliable cycle times

- Multiple belt and slurry combinations allow UFF to polish glass, crystal, ceramic and metal aspheric and freeform optics

-

Specs

UFF 500 Technical Specifications

UltraForm Finishing Machine Specifications* PRO 80 UFF PRO 160 UFF UFF 300 UFF 500 Workpiece Optimal Diameter Range 10-80 mm (.39-3.14") 10-160 mm (.39-6.3") 10-300 mm (.39-11.8") 25-500 mm (.98-19.7") Maximum Plano Diameter** 100 mm (3.9") 200 mm (7.87") 300 mm (11.8") 500 mm (19.7") Maximum Weight 15 kg (33 lbs.) 25 kg (55 lbs.) 23 kg (51 lbs.) 170 kg (374.8 lbs.) Work Spindle** Spindle Speed 0-1,500 RPM 0-600 RPM 0-500 RPM 0-200 RPM Hydro-Expansion Standard Standard Standard Standard Vacuum Chuck Standard Standard Standard Standard C-Axis Position and Hold Standard Standard Standard Standard Travels X-Axis Travel 250 mm (9.8") 420 mm (16.5") 500 mm (19.7") 1,200 mm (47.2") Y-Axis Travel 6 mm (0.24") 6 mm (0.24") 400 mm (15.7") 700 mm (27.6") Z-Axis Travel 140 mm (5.5") 220 mm (8.7") 500 mm (19.7") 500 mm (19.7") B-Axis Travel -60° to 60° -60° to 60° -90° to 90º -90° to 90° C-Axis Travel 0 ° to 360° 0 ° to 360° 0 ° to 360° 0 ° to 360° Communication Interface Ethernet Standard Standard Standard Standard USB Standard Standard Standard Standard Machine Dimensions Width 1,000 mm (39") 1,400 mm (55") 2,110 mm (83") 2,570 mm (101") Depth 1,500 mm (59") 1,730 mm (68") 2,515 mm (99") 3,700 mm (146") Height 2,440 mm (96") 2,440 mm (96") 2,700 mm (106") 3,020 mm (119") Weight 1,600 kg (3,500 lbs.) 1,950 kg (4,300 lbs.) 3,400 kg (7,500 lbs.) 5,750 kg (12,650 lbs.) Workpiece Probing Standard Standard Standard Standard Tool Probing Standard Standard Standard Standard Asphere Fabrication Standard Standard Standard Standard Non-Rotationally Symmetric Correction Optional Optional Optional Optional Freeform Fabrication N/A N/A Optional Optional * Specifications subject to change. Contact OptiPro for the latest specifications.

** Machine is capable of manufacturing maximum plano size in small volume. For medium and large production quantities of max plano size, consider OptiPro’s larger platform.